Back to Product Category

Roughneck

WIRE MESH SLINGS

TYPE 1 |

Specialty

Slings with Particular Properties and Uses |

Widely used

in metalworking shops and steel warehouses where loads are abrasive, hot

or tend to cut web slings. |

|

|

|

|

Select

The Proper Mesh |

|

10

Gage-Heavy Duty |

12

Gage-Medium Duty |

|

|

|

|

|

|

|

|

|

|

|

| Roughneck

Wire Mesh Sling Construction - 10 Gage Standard |

|

|

|

|

| Alloy

steel end fittings are zinc plated. Mesh is 10 gage galvanized high tensile

steel (12 gage upon request). |

|

|

|

|

| Optional: Type 304 stainless steel mesh is availablefor use in corrosive environments. |

|

HOW

TO ORDER WIRE MESH SLINGS |

|

|

|

|

|

* * |

Do not

edge load. Full width of mesh must contact load. |

|

| |

|

|

|

|

|

|

|

|

|

|

Under

normal usage, wire mesh slings will

eventually need repairs. We can perform this

service and re-certify all sling brands at a relatively

low cost. Wire mesh slings that are repaired are

guaranteed to meet or exceed original specifications.

Five Lift-All factories are strategically located in the

U.S. to ensure prompt service. Wire mesh slings

should be removed from service and/or repaired

under the following conditions: |

Wire Mesh

Width (in.) |

Rated

Capacity (lbs.)* |

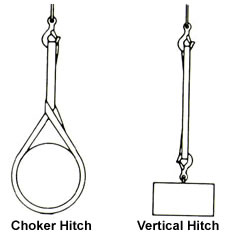

| Vertical |

Choker

(Type 1 Only) |

Vertical

Basket |

10

Gage - Heavy Duty |

|

|

|

| 2 |

2,300 |

2,300 |

4,600 |

| 3 |

3,500 |

3,500 |

7,000 |

| 4 |

4,800 |

4,800 |

9,600 |

| 6 |

7,200 |

7,200 |

14,400 |

| 8 |

9,600 |

9,600 |

19,200 |

| 10 |

12,000 |

12,000 |

24,000 |

| 12 |

14,400 |

14,400 |

28,800 |

| 14 |

16,800 |

16,800 |

33,600 |

| 16 |

19,200 |

19,200 |

38,400 |

| 18 |

21,600 |

21,600 |

43,200 |

| 20 |

24000 |

24000 |

48,000 |

|

|

|

|

|

|

|

|

• A broken

weld or brazed joint along the sling edge.

• A broken wire in any part of the mesh.

• Reduction in wire diameter of 25% due to

abrasion or 15% due to corrosion.

• Lack of flexibility due to distortion of the mesh.

• Visible distortion or wear of either end fitting.

• Cracked end fitting. |

|

|

|

|

|

NOTE: The choker fitting must be positioned against a

load edge or directly on the triangle fitting. |

|

| 12

Gage - Medium Duty |

| 2 |

1,600 |

1,600 |

3,200 |

| 3 |

2,400 |

2,400 |

4,800 |

| 4 |

3,200 |

3,200 |

6,400 |

| 6 |

4,800 |

4,800 |

9,600 |

| 8 |

6,400 |

6,400 |

12,800 |

| 10 |

8,000 |

8,000 |

16,000 |

| 12 |

9600 |

9600 |

19,200 |

|

|

|

|

|

|

|

|

Nominal

Width

(in.) |

Terminal

Dimensions (in.) |

Terminal

Thick.

(in.) |

Approx.

Wt.

of 3 ft. Slings

(lbs.) |

Mesh

Wt.

(Per ft. in lbs.) |

| MW |

D |

IL |

TL |

CL |

10

GA |

12

GA |

10

GA |

12

GA |

10

GA |

12

GA |

| 2 |

2 |

3 |

3

7/8 |

5

5/8 |

1/2 |

1/2 |

6 |

5 |

1.3 |

1.1 |

| 3 |

2

1/4 |

3

3/8 |

4

3/8 |

6

1/4 |

1/2 |

1/2 |

8 |

8 |

1.9 |

1.8 |

| 4 |

3 |

4 |

5 |

6

3/4 |

1/2 |

1/2 |

10 |

10 |

2.5 |

2.3 |

| 6 |

3

1/2 |

4

1/2 |

5

5/8 |

7

3/4 |

1/2 |

1/2 |

16 |

14 |

3.9 |

3.4 |

| 8 |

4

1/2 |

6 |

7

1/2 |

9 |

1/2 |

1/2 |

22 |

21 |

5.1 |

4.5 |

| 10 |

4

3/4 |

6

1/4 |

8 |

10

7/8 |

1/2 |

1/2 |

28 |

26 |

6.4 |

5.6 |

| 12 |

5 |

6

1/2 |

8

5/8 |

11

3/8 |

1/2 |

1/2 |

34 |

32 |

7.6 |

6.8 |

| 14 |

5 |

6

1/2 |

8

3/4 |

12

3/4 |

1/2 |

1/2 |

40 |

37 |

8.9 |

7.9 |

| 16 |

5

1/4 |

7 |

9

1/8 |

14

1/8 |

3/4 |

1/2 |

57 |

38 |

10 |

9 |

| 18 |

5

1/2 |

7

1/2 |

9

3/4 |

15

3/4 |

3/4 |

1/2 |

67 |

44 |

11 |

10 |

| 20 |

5

3/4 |

7

3/4 |

10

1/8 |

17 |

3/4 |

1/2 |

77 |

51 |

13 |

11 |

|

|

|

Do

not exceed rated capacities. Sling capacity decreases as the angle from

horizontal decreases. Slings should

not be used at angles of less than 30°. Refer to the Effect of Angle

chart in bottom of page. |

* |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click a Price of the item you wish to purchase. |

|

|

Nominal

Width

(in.) |

Extended

Prices @ Lengths Shown (ft.) |

| 3' |

4' |

5' |

6' |

8' |

10' |

12' |

14' |

16' |

18' |

20' |

| MW |

2 |

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

6 |

|

|

|

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

10 |

|

|

|

|

|

|

|

|

|

|

|

12 |

|

|

|

|

|

|

|

|

|

|

|

14 |

PRICE

UPON REQUEST |

16 |

PRICE

UPON REQUEST |

18 |

PRICE

UPON REQUEST |

20 |

PRICE

UPON REQUEST |

| Type

1 - 12 Gage |

Nominal

Width

(in.) |

Extended

Prices @ Lengths Shown (ft.) |

| 3' |

4' |

5' |

6' |

8' |

10' |

12' |

14' |

16' |

18' |

20' |

| MW |

2 |

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

6 |

|

|

|

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

10 |

|

|

|

|

|

|

|

|

|

|

|

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| EFFECT

OF SLING ANGLE |

|

|

|

|

|

|

|

|

|

Using

slings at an angle can become deadly if that angle is not taken into

consideration when selecting the sling to

be used. The tension on each leg of the sling is increased as the angle

of lift, from horizontal, decreases. It is most

desirable for a sling to have a larger angle of lift, approaching 90°.

Lifts with angles of less than 30° from horizontal

are not recommended. If you can measure the angle of lift or the length

and height of the sling as rigged, you can

determine the properly rated sling for your lift. The Increased Tension

method provides the increased tension as a

function of the sling angle. Alternatively, the sling Reduced Capacity method

may be used to determine reduced lift

capacity for any angle. |

|

|

|

|

|

|

|

|

|

INCREASED

TENSION

Determine capacity

of sling needed |

|

REDUCED

CAPACITY

Calculate rating of each sling

rigged at this angle |

|

|

|

|

|

| 1.

Determine the load weight (LW). |

1.

Calculate the reduction factor (RF). |

|

|

|

|

a.

Using the angle from horizontal,

read across the Angle Chart to

the corresponding number of the

Reduction Factor column. |

| 2.

Calculate the Tension Factor [TF]. |

|

|

a.

Determine the sling angle as mea-

sured from the horizontal, and the

corresponding tension factor (TF)

from the effect of angle chart. |

|

|

|

-OR- |

|

|

b.

Divide sling height* (H) by sling

length* (L). |

|

-OR- |

|

|

|

b.

Length* (L) divided by height*

(H) |

|

|

|

|

|

2.

Reduction factor (RF) x the sling’s

rated capacity for the type hitch that

will be used = sling’s reduced rating. |

|

|

|

|

|

|

|

|

|

|

|

|

3.

Determine the share of the load

applied to each sling leg (LW). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4.

Multiply (LW) by (TF) to determine

the sling leg tension. The capacity of

the selected sling or sling leg must

meet the calculated tension value. |

|

|

*Measured

from a common horizontal

plane to the hoisting hook. |

|

|

|

|

|

|

|

|

|

|

|

|

*Measured

from a common horizontal plane

to the hoisting hook. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Effect

of Angle Chart |

|

|

|

|

Tension

Factor (TF) |

Angle From

Horizontal |

Reduction

Factor (RF) |

| 1.000 |

90º |

1.000 |

| 1.004 |

85º |

0.996 |

| 1.015 |

80º |

0.985 |

| 1.035 |

75º |

0.966 |

| 1.064 |

70º |

0.940 |

| 1.104 |

65º |

0.906 |

| 1.155 |

60º |

0.866 |

| 1.221 |

55º |

0.819 |

| 1.305 |

50º |

0.766 |

| 1.414 |

45º |

0.707 |

| 1.555 |

40º |

0.643 |

| 1.742 |

35º |

0.574 |

| 2.000 |

30º |

0.500 |

|

|

|

|

|

|

|

|

|

Example: |

|

|

|

Vertical

Choker rating of each sling:

6,000 lbs.

Measured Length (L) = 6 ft.

Measured Height (H) = 4 ft.

Reduction Factor (RF) = 4 (H) ÷ 6 (L) = .667 |

|

|

|

|

| Example: |

|

|

|

Load

weight = 1,000 lbs.

Rigging - 2 slings in vertical hitch

Lifting Weight (LW) per sling = 500 lbs.

Measured Length (L) = 10 ft.

Measured Height (H) = 5 ft.

Tension Factor (TF) = 10 (L) ÷ 5 (H) = 2.0

Minimum Vertical Rated Capacity required

for this lift = 500 (LW) x 2.0 (TF) = 1000 lbs.

per sling |

|

Sling

capacity decreases as the angle

from horizontal decreases. Sling angles

of less than 30° are not recommended. |

|

|

Reduced

sling rating in this configuration

= .667 |

|

(RF)

x 6,000 lbs. = 4,000 lbs. of lifting

capacity per sling |

|

|

|

|

|

|

|

Wire Mesh Slings, Lifting

Slings, Lift-All, Sling, 10 Gage-Heavy Duty, 12 Gage-Medium Duty, Steel

Construction,

Stamped with Capacity and Serial Number, Sling Proof Tested and Certified,

Grips Load firmly without stretching,

Resists Abrasion, and Mesh is Galvanized from your source for material

handling equipment. |

Back to Product Category

|