|

|

|

|

|

|

|

Easy to Operate

Easy to Operate |

|

|

Ergonomic Handling

Ergonomic Handling |

|

VT

tube lifting systems require minimal operator training.

VT systems grab the load (via vacuum suction), support,

lift and lower the load, all by a single operator control.

The use of vacuum pads for attachment allows objects

to be lifted without fear of damage to the surface or

edges of the product, often caused by manual lifts or

grabs. |

|

|

|

VT

Vacuum Tube Lift Systems are ideal for repetitive

handling of either non-porous, semi-porous or porous

loads. Models are offered to handle loads from 5 lb.

(2.3 kg) for non-porous loads, all the way up to

660 lb. (300 kg). Actual system capabilities vary

based upon the tube size, pad attachment and vacuum

station used. |

|

|

|

|

|

|

Quality Design

Quality Design |

|

|

|

|

All

VT lifting systems feature stainless steel construction throughout.

A wide assortment of vacuum pad attachments makes

a VT System ideal for many material handling needs. |

|

|

|

|

|

|

|

|

|

|

Vacuum

tube lifting systems are rapidly becoming the system of

choice where single operator material handling of repetitive

or

heavy loads is required. Systems are in use at many of the

largest

US manufacturers, yet their affordable pricing have made them

a

practical tool for the smallest companies. |

|

|

|

|

|

|

Vacuum

tube lifters are used for packing TV's, small appliances,

computer equipment, furniture, virtually any item to which

a

vacuum pad can be attached. Palletizing, stacking, loading

and

un-loading bags, sacks, cartons, printed material, buckets,

drums,

pails and woven goods are among the typical uses. Raw materials

can be lifted and lowered into position for weighing, emptying,

or

mixing ingredients in the food, chemical or pharmaceutical

industries. |

|

|

|

|

VT

lifting systems have also found their place in the manufacturing

assembly process for lifting and placing items into position,

such as

lifting a TV picture tube into its chassis. |

|

|

|

|

|

|

|

|

|

|

|

Easy to Use and Install

Easy to Use and Install |

|

|

A

VT Vacuum Tube Lifter uses vacuum to both attach to and lift

a load, eliminating the need for chain hoists or manipulators.

When the system's vacuum pads touch the load, the air flow

is

blocked, causing the vacuum level to increase until the load

is

lifted. A hand valve allows just enough leakage of air to

control

speed and height. When the load is set down, the valve is

opened

fully to release the load. |

|

|

|

|

|

|

|

|

|

Experience Counts

Experience Counts |

|

|

Our

applications engineers can provide a thorough technical review

of your system requirements and help you select the right

vacuum lifter for your needs and budget from our extensive

range of standard as well as specialized systems. |

|

|

|

|

|

|

| TO

SEE SPECIFICATIONS FOR YOUR LOAD RANGE CLICK ON A LINK BELOW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

To

request a quote, or phone consultation, please click on the

'Quote' link at the

top (or bottom) of the page to submit your information. |

|

|

|

|

| Features

found in every VT Vacuum Tube Lifting System: |

|

|

|

|

|

|

|

|

|

Easy to Maneuver

Easy to Maneuver |

|

|

Winning

universal acceptance among operators, VT Tube Lift

systems have little bulk yet feel secure. The lifting tube

bears

all the load weight, allowing the operator to effortlessly

maneuver

and position the load. |

|

|

|

|

Simple to Operate

Simple to Operate |

|

|

A

VT system is simple to operate and easily adjusts to any

working height. Training is minimal; most operators become

productive within minutes. |

|

|

|

|

|

Once

properly mounted, the VT system becomes an ergonomic

tool that increases productivity while reducing labor content

in

the work place. |

|

|

|

|

Corrosion Resistant

Corrosion Resistant |

|

|

External

surfaces combine stainless steel, anodized aluminum,

epoxy- coated metal, and nylon components, all FDA approved

for washdown and food service applications. |

|

|

|

|

|

|

|

|

|

|

|

Following

items are

standard for each

VT System: |

|

|

Vacuum station with Muffler

Vacuum station with Muffler |

|

|

Lifting Tube with Top Swivel

Lifting Tube with Top Swivel

and Control Head |

|

|

Filter with Vacuum Gauge

Filter with Vacuum Gauge |

|

|

Vacuum Hose

Vacuum Hose |

|

|

Free Pad Attachment

Free Pad Attachment |

|

|

Instruction

Manual

Instruction

Manual |

|

|

2/1 Year Warranty

2/1 Year Warranty |

|

|

30-Day Performance

30-Day Performance

Guarantee |

|

|

|

|

|

VT

Tube Lift Systems can be mounted to any

overhead, wall or pedestal mount jib or

workstation crane. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Vacuum Gauge on the Control

Vacuum Gauge on the Control

Head |

|

Simple 'Hand Squeeze

Simple 'Hand Squeeze

Against Spring Resistance'

(Adjustable) Control |

|

|

VT

Tube Lift Systems are equipped

with a vacuum gauge on the control

head to readily indicate to the

operator that the load is securely

attached and ready for lifting. |

|

|

|

|

|

The

ergonomically designed

control handle has made the unit

a favorite among operators. The

control is activated by simply

squeezing the ever with the thumb

and fingers in a natural grasping

motion. |

|

|

|

|

|

|

|

|

Multi-function Lift Control

Multi-function Lift Control |

|

|

|

|

Micro-adjustment

of tube lift

and acceleration are

accomplished with the same

control on the front handle that

regulates air suction power.

Stainless steel adjustment knobs

and nylon valve seats on the

control head ensure accurate and

consistent settings every time. |

|

|

|

|

|

|

|

|

|

|

|

Improved Conical Flow

Improved Conical Flow

Control Valve |

|

|

|

|

The

redesigned conical flow

valve allows the operator to

precisely control the vacuum

power, resulting in a much

smoother, more ergonomic

and user-friendly control

than competitive units. |

|

|

|

|

|

|

|

|

|

Power Loss Check-Valve

Power Loss Check-Valve |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

In

the event of an electrical

power failure or pump mal-

function, a check valve helps

to maintain vacuum in the lift

tube, allowing on elevated load

to slowly and gently descend

back to the floor. |

|

Double Layer Reinforced

Double Layer Reinforced

Lift Tubes |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Vacuum

Lift Tubes feature a

heavy-duty steel wire-reinforced

construction surrounded by a

double cloth, which is then film

wrapped, reducing the chance

of vacuum leakage. |

|

|

|

|

|

|

|

|

PVC Cuffs and Stainless Clamps

PVC Cuffs and Stainless Clamps |

|

|

|

|

|

|

|

|

|

|

|

|

|

In

addition to the use of quality

kink-free supply hoses, our

systems include PVC hose

cuffs and stainless steel clamps

throughout for solid, vacuum-

tight connections. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Vacuum Pad Attachment Included

Vacuum Pad Attachment Included

with Each Complete System |

|

Fully Adjustable Vacuum Pad

Fully Adjustable Vacuum Pad

Attachments |

|

|

|

Every

VT Tube Lift system price includes

a vacuum pad attachment chosen by our

applications engineers to suit the job at

hand. No need to consider a pad attachment

as an additional add-on cost item. |

|

|

All

Vacuum Pad Attachments offer heavy-

duty construction and corrosion resistance.

Multiple pad attachments offer

independently adjustable pad slides

mounted on an aluminum channel with

knurled locking knobs. Pads feature spring

action clevis mounts to allow handling of

open flaps as well as sealed cartons. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Quick Disconnect

Quick Disconnect |

|

|

|

|

|

|

|

Quick

Disconnects for pad attachments

adjust a full 360° and can be locked into

position, an Exclusive Feature. We also

offer a unique snap-into-position feature

that allows pads to rotate 90° and then lock into place. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

In-line Filters to protect

In-line Filters to protect

Vacuum Pumps |

More Lift Capacity per Pad Size

More Lift Capacity per Pad Size |

|

|

|

|

Full Range of Options and

Full Range of Options and

Accessories |

|

|

|

Our

use of direct-drive pumps

produces 18" Hg vacuum vs. the

12"-16" Hg competitive units

produce with belt-drive pumps. |

|

|

|

|

|

|

|

VT

Tube Lift systems include in-line

air filters to protect the vacuum pump

from unnecessary wear. A vacuum gauge

mounted on the filter aids in monitoring

the system vacuum level. |

|

|

|

|

|

|

|

|

We

offer a wide range of optional

accessories to adapt our systems

to virtually any lifting requirement,

including extended length control

handles, tube head pad extensions,

drum filters, special length vacuum

tubes and supply hoses, and sound

deadening pump enclosures. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

As

a result, a VT System with a 140 mm

diameter tube is able to lift the same

loads as competitive units equipped

with a 160 mm diameter tube. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Low Maintenance

Low Maintenance |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Superior

engineering and meticulous

workmanship make VT Tube Lift

systems highly reliable with minimal

downtime. Maintenance-free pumps

eliminate complicated and time-

consuming servicing. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fast, Smooth Operation

Fast, Smooth Operation |

|

|

|

|

|

|

|

|

|

VT

Vacuum Tube Lift systems have a

high duty cycle and can operate

continuously with unlimited stops and

starts, making the systems ideal for

high-speed production line applications. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

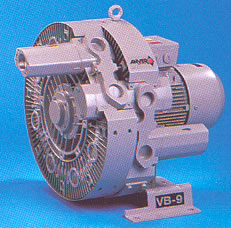

Direct-Drive Vacuum Pumps

Direct-Drive Vacuum Pumps |

|

|

|

|

|

|

|

VT

Tube Lift systems include only

special high efficiency models of

vacuum pumps built exclusively for

us. These precision die-cast, direct

drive pumps have made other pumps

obsolete for vacuum tube lifting

applications. |

|

|

|

|

|

|

|

|

|

|

|

|

See

bottom of page for Vacuum

Station information |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| TO

SEE SPECIFICATIONS FOR YOUR LOAD RANGE CLICK ON A LINK BELOW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MINI

VACUUM TUBE SYSTEMS (VT100, VT120,VT140)

(high efficiency load lifting

up to 195 lb.) |

STANDARD

VACUUM TUBE SYSTEMS (VT160, VT180, VT200)

(corrosion-resistant load lifting up to 375 lb.) |

LARGE

CAPACITY VACUUM TUBE SYSTEMS (VT250, VT2200)

(heavyweight load lifting up to 660 lb.) |

|

|

VACUUM

PUMPS FEATURE:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

These

revolutionary regenerative pumps offer a compact, reliable

source of

quiet, vibration-free vacuum. Our quality pumps are made from

tough, high-

strength materials for long life and are lightweight and virtually

maintenance

free. Their highly efficient, state-of-the-art design has

made older designs of

conventional side-channel blowers obsolete. Pumps are available

capacities

of up to 480+ cfm flow and 18 in. Hg vacuum. Powered by high

quality

TEFC Siemens motors, they are more energy efficient require

less horse-

power to operate than competitive models, and are offered

in several sizes

to match your vacuum lifting requirements. |

|

|

|

|

|

|

|

|

|

|

High Flow Pumps

High Flow Pumps |

Ideal for Bags and Boxes

Ideal for Bags and Boxes |

|

|

For

porous loads, we offer High

Flow models of Siemens re-

generative pumps. These

revolutionary pumps provide a

compact and reliable source of

quiet, vibration free vacuum. |

|

Producing

up to 12 in. Hg and

320 scfm of flow, these pumps

are an ideal choice for vacuum

lifting of extremely porous bags

and boxes. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

High Vacuum Pumps

High Vacuum Pumps |

|

Porous Load Lifting

Porous Load Lifting |

|

|

|

|

We

also offer the latest design of

Siemens high-efficiency regenerative

pumps in our VT vacuum tube lifting

systems. |

Low Noise Level

Low Noise Level |

|

These

High Flow Regenerative

Pumps are recommended for lifting

porous or semi-porous material,

such as plywood panels, bags or

printed material and are also used

in VB Vacuum Lifting Systems. |

|

|

Powered

by high-quality Siemens

TEFC motors, their rated operating

noise levels are 71 to 76 dB or less.

Sound deadening enclosures to

further reduce noise levels by 6 dB

are available. |

|

|

|

|

|

|

Constant Vacuum

Constant Vacuum |

|

|

|

Capable

of generating a lifting

vacuum of 18 in. Hg with a flow

capacity of 60 to 125 cfm or more,

high-efficiency regenerative pumps

are ideal for handling non- or semi-

porous loads where conventional

pumps would be inadequate or where

high maintenance rotary vane pumps

were formerly used. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Easy Installation

Easy Installation |

|

|

|

|

|

|

|

|

Regenerative

Vacuum

Pumps can be mounted

in any position with four

mounting bolts. The

mounting plate features

shock absorption to

prevent vibration

transmission. |

|

|

|

|

|

|

Economically Priced

Economically Priced |

|

|

|

|

Our

large volume purchasing power

allows us to offer any of these high

quality pumps as standard with all

our VT vacuum tube lifting systems

while still maintaining economical

system prices. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

High Efficiency Pumps

High Efficiency Pumps |

|

|

|

|

|

|

High

Efficiency High Vacuum Regenerative Pumps feature a compact

design and are ideally suited for vacuum tube lifting of heavy,

non-porous

to semi-porous loads. They achieve a high vacuum level (18

in. Hg) while

being the quietest (71 dB) in the industry. |

|

|

|

|

|

Sound Deadening Enclosures

Sound Deadening Enclosures |

|

|

|

|

Pumps for Special Applications

Pumps for Special Applications |

|

Optional

sound deadening enclosures can reduce

operating noise by approximately 6 dB. |

|

|

|

|

For

specialized lifting applications, we are able to offer

alternate vacuum stations, including systems with pumps

designed for use in hazardous duty, explosive

environments and for wash-down applications. |

|

|

|

|

Energy Efficient

Energy Efficient |

|

|

|

These

pumps are far more energy efficient, require less

horsepower, and operate at a speed of only 3500-rpm

vs. the 7000-rpm common with belt-drive pumps. |

|

|

|

|

|

|

|

|

Optional Mounting

Optional Mounting |

|

|

|

Optional

stands and wall mounting brackets are

available to assist in locating these vacuum pumps

away from the work area. |

|

|

|

|

Ready to Use

Ready to Use |

|

|

|

All

regenerative pumps are equipped with exhaust

mufflers, filters with vacuum gauges for monitoring

the overall system performance, fittings, and hose,

Vacuum relief valves to prevent the pumps from

operating under a deadhead condition are optionally

available. |

|

|

|

|

|

|

|

|

Optional Wireless Remote Control

Optional Wireless Remote Control |

|

|

|

All

tube lift systems can be fitted with a wireless

remote control for powering the vacuum pump, useful

when the pump is mounted remotely from the

operator's station. The remote control can be attached

to the lifter control head or supplied with a belt clip to

be worn by the operator. |

|

|

|

|

|

|

|

|

|

|

To

request a quote, or phone consultation, please click on

the 'Quote' link at the

top (or bottom) of the page to submit your information.

|

|

|

|

|

|

We

also offer the latest

revolutionary designed Liquid

Ring Water cooled Vacuum

Pumps. Once filled, the TCP

series requires no external

water supply or oil while

maintaining an operating

temperature below 110°F

(43°C). This ingenious design

makes the TCP ideal for

continuous duty or hazardous

material applications. |

A

wide assortment of

additional pumps for special

applications can also be

supplied. Vacuum Pumps with

higher vacuum or higher air

flow are available, as well as

units for use in hazardous

duty and explosive

environments. |

We

produce many lines of

compressed air powered

vacuum pumps including a line

of Multi-Ejector pumps suitable

for Tube Lifting Systems.

These Air Pumps can be used

on the smaller VT90 and VT100

systems for installations where

a dedicated supply of clean,

dry, shop air is readily available. |

We

also offer replacement parts

and complete belt-drive stations

for older systems. Since many

older systems were built with

these belt drive pumps, we can

offer various popular size for

all competitive systems. |

|

|

|

|

|

|

|

|

|

|

| TO

SEE SPECIFICATIONS FOR YOUR LOAD RANGE CLICK ON A LINK BELOW |

|

|

|

|

|

|

|

|

STANDARD

VACUUM TUBE SYSTEMS (VT160, VT180, VT200)

(corrosion-resistant load lifting up to 375 lb.) |

LARGE

CAPACITY VACUUM TUBE SYSTEMS (VT250, VT2200)

(heavyweight load lifting up to 660 lb.) |

|