Back to Product Category

Engineering

Matters – Below the Hook Lifting Devices |

Below

the Hook Lifters are those helpful pieces of equipment that provide a connection

point between the crane and

the load being lifted. They can be structural mechanical lifting devices,

vacuum lifters, magnets, and grapples. In order

to provide direction regarding the design, marking, installation, inspection

testing and much more, the American Society

of Mechanical Engineers (ASME) has developed standards that apply specifically

to these types of devices.

In 2006 The American Society

of Mechanical Engineers released a new standard, ASME BTH-1 in order to

provide

clarification in regards to structural design requirements stated in ASME

B30.20. The revision to ASME B30.20 that

fully references ASME BTH-1 was published in January 2007 and became effective

January 16, 2008. This new

standard applies to all new product manufactured after January 16, 2008

and does not require that existing below the

hook lifting devices be reworked to adhere to the new standard requirements.

ASME B30.20 provides detailed

information on the classifications, marking, construction, installation,

inspection,

testing, maintenance, and operation of below the hook lifting devices.

ASME BTH-1 provides detailed information

on the design criteria of below the hook lifting devices. Here are some

Quick Facts you need to know about below

the hook lifting devices

|

|

|

|

|

|

|

Quick

Facts |

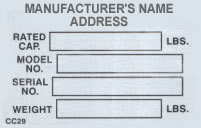

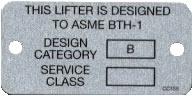

| Marking: Below the hook lifting devices shall be marked with at least: |

|

•

Manufacturer’s name and address

• Serial number

• Lifter weight, if over 100 lbs. (45 kg)

• Cold current (amps) (when applicable)

• Rated voltage (when applicable)

• Rated load

• ASME BTH-1 Design Category

• ASME BTH-1 Service Class

• Product Safety Labels |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Service

Class: Will determine the approximate life of a lifter: |

|

| Service

Class |

Load Cycles |

| 0 |

0 - 20,000 |

| 1 |

20,001 - 100,000 |

| 2 |

100,001 - 500,000 |

| 3 |

500,001 - 2,000,000 |

| 4 |

Over 2,000,000 |

|

|

|

|

|

| Installation: Lifting Equipment shall assembled and installed in accordance with the

manufacturer’s instructions.

Operator Training: Lifters

shall be operated in accordance with manufacturer’s operating instructions

and by

personnel who have received instructions in proper Operating Practices.

Inspection: The lifter

shall be visually inspected by or under the direction of an appointed

person on a daily or weekly

schedule and by the operator prior to each lift.

Maintenance & Repairs: A preventative maintenance program should be established for each

lifter. Repairs shall

be in accordance with ASME standards. Replacement parts shall be at least

equivalent to the original manufacturers

specifications.

|

|

|

|

| Operating

Practices:

|

•

Do inspect the lifter prior to each lift.

• Do read and understand all operating instructions.

• Do watch carefully during the lift.

• Don’t use a lifter with an out of service tag.

• Don’t use a lifter for any other purpose than it was designed.

• Don’t obscure markings or use a lifter when the markings are

not legible or missing. |

|

|

|

| Handling

the Load:

|

•

The lifter shall not be loaded in excess of its rated capacity.

• The lifter shall be applied to the load as directed by the manufacturer.

• All loads shall be accelerated and decelerated smoothly.

• The operator or other personnel shall not place themselves or any

part of their bodies beneath suspended loads. |

|

|

|

This

information is a very brief summary of what you need to look for in order

to make an informed decision regarding

the Lifting Devices you are considering or have already purchased. For more

details contact us. |

|

|

|

Standards, ASME Standards,

American Society of Mechanical Engineers Standards, Below the Hook Lifting

Devices,

Hook Suspended Lifting, Vacuum Lifter, Suction Lifting, and Vacuum Lifting

Equipment from your source for material

handling equipment. |

Back to Product Category

|