Back to Product Category

SEQ

SERIES ELECTRIC CHAIN HOISTS

DUAL SPEED (VFD CONTROL) |

|

|

|

|

|

|

|

|

|

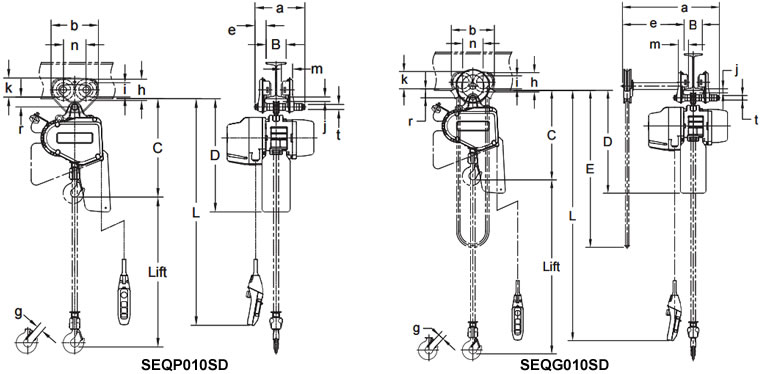

SEQ010SD |

|

SEQP010SD |

|

SEQG010SD |

|

|

|

|

|

|

|

|

SEE

BELOW FOR PRICES, SPECIFICATIONS AND DIMENSIONS |

|

|

|

|

|

|

|

|

|

V A R

I A B L E F R E Q U E N C Y D R I V E – V F D

(INVERTER FOR SMOOTH TRANSITIONAL SPEED) |

|

The

dual speed inverter delivers smoother movement than contactor control which

reduces load swing. The inverter

can be programmed to operate specific to the application, resulting in smooth

starts, improved control, improved

positioning accuracy and overall increased productivity. Standard lifting

speed ratio is 6:1. Standard traversing

speed ratio is 6:1 adjustable to 10:1.

A no-load high-speed function is a standard feature, allowing its hoisting

speed to move 1.3 times faster during no-

load operation. When the no-load condition is detected by the inverter,

this function is activated automatically

switching to high-speed operation, leading to improved work efficiency with

ease and safety. The function is easily

activated (ON/OFF) with the push button control.

EQ, EQM and SEQ inverter units are well-customized for lifting/traversing

applications including exclusive software,

and are also provided with measures against impact and heat, which were

verified through long-run tests. |

|

|

|

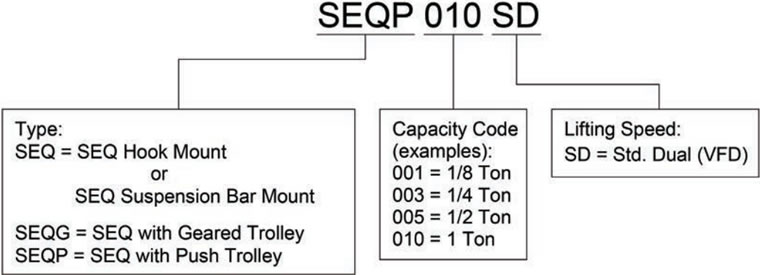

| Product

Code for SEQ Series |

|

|

|

SEQ

Electric Chain Hoist Hook or Suspension Bar Mount |

|

|

|

|

|

|

SEQ

Series single-phase dual speed (VFD Control) electric chain hoists are designed

for

easy installation and operation in medium- and heavy-duty industrial applications.

These

hoists have an extremely compact and lightweight body and are perfect for

any work station

application. The SEQ hoist includes a no-load high-speed function that automatically

increases hoist speed up to 130 percent when the load is less than 30 percent

of working

load limit. |

|

|

|

|

Standard

Hoist Specifications |

|

Capacity

Range - 1/8 Ton – 1 Ton

Standard Voltage - 115/230-1-60

Control Voltage - 24V

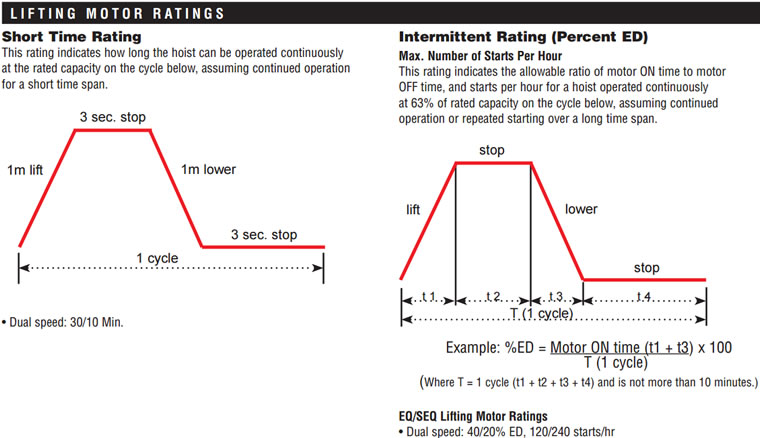

Duty Cycle* - 30/10 Min.

Classification* - ASME H4 ISO 1/8-1/2T M6; 1T M5 FEM 1/8-1/2T 3m;

1T 2m

Conformance - UL 508, 508A, 1004 CSA C22.2 NO. 33, 14-13, 66

Ratings - Hoist – IP55, Pendant – IP65

Chain Falls - Single chain fall all capacities

Standard Lift - 10' (longer lifts available)

Standard Pendant Drop - 4' less than lift (longer drops available)

Standard Power Supply Length - 15' (longer lengths available)

Mounting - Hook, suspension bar or trolley

Standard Pendants - 2-button (momentary contacts) with emergency

On/Off (maintained

contacts)

Chain Containers - Standard plastic

Operating Conditions - Recommended for -4° to +104° F and

humidity of 85% or less |

|

|

|

| SEQ010SD |

|

|

|

|

|

| Features

and Benefits |

|

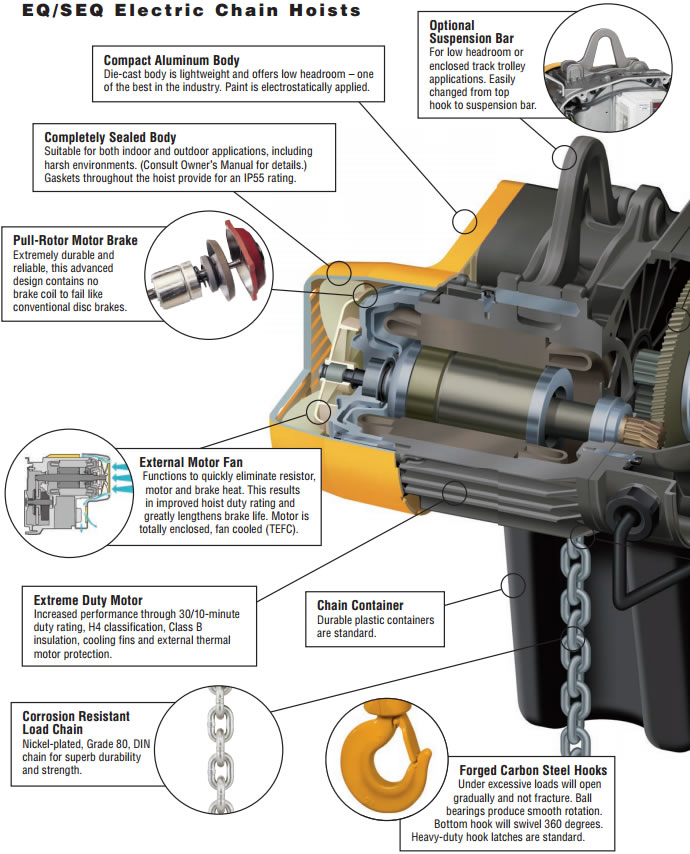

Pull-Rotor

Motor Brake - Extremely durable and reliable, this advanced design contains

no brake coil to fail like

conventional disc brakes.

External Motor Fan - Functions to quickly eliminate resistor, motor

and brake heat. This results in improved hoist

duty rating and greatly lengthens brake life. Motor is totally enclosed,

fan cooled (TEFC).

Precision Machined Helical Gears - Immersed in oil bath lubrication

results in quiet, smooth and cool operation.

Chain Container - Durable plastic containers are standard.

Corrosion Resistant Load Chain - Nickel-plated, Grade 80, DIN chain

for superb durability and strength.

Forged Carbon Steel Hooks - Under excessive loads will open gradually

and not fracture. Ball bearings produce

smooth rotation. Bottom hook will swivel 360°. Heavy-duty hook latches

are standard.

Optional Suspension Bar - For low headroom or enclosed track trolley

applications. Easily changed from top hook

to suspension bar.

Compact Aluminum Body - Die-cast body is lightweight and offers low

headroom – one of the best in the industry.

Paint is electrostatically applied.

Completely Sealed Body- Suitable for both indoor and outdoor applications,

including harsh environments. (Consult

Owner’s Manual for details.) Gaskets throughout the hoist provide for

an IP55 rating.

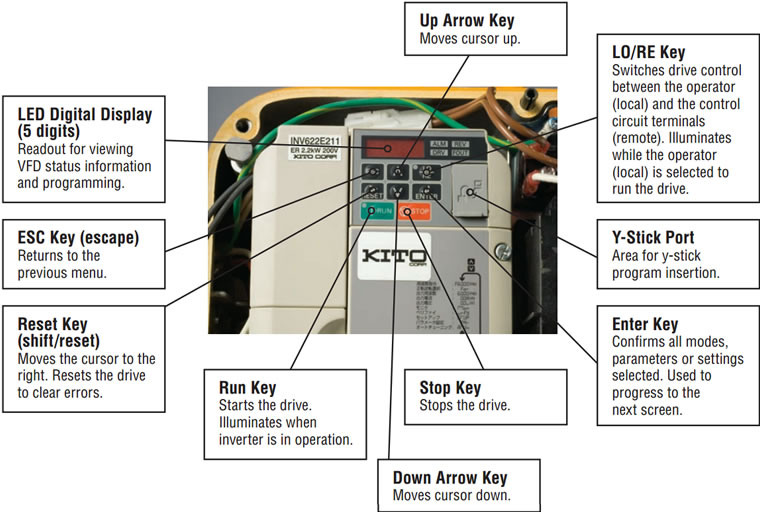

Variable Frequency Drive (VFD) - Dual speed controls via “under-the-cover”

variable frequency drive for both

single-phase and three-phase hoists. VFD includes count hour meter, load

limiter and no-load high-speed function.

Long Life Friction Clutch - Protects hoist from damage and prevents

overwinding.

Upper/Lower Limit Switch - Low profile upper and lower limit switches

provide excellent headroom.

Unique Chain Guide - Provides quiet and smooth guiding of chain.

Heavy cast iron construction for improved wear

versus stamped steel design offered by many manufacturers.

Durable Push Button Pendant - Easy-to-use, one-handed operation.

Rated IP65. Standard control voltage is 24V.

Strain relief wire is molded to pendant cord for added support and dependability.

E-Stop is standard on all pendants.

Extreme Duty Motor - Increased performance through 30/10-minute duty

rating, H4 classification, Class B insulation,

cooling fins and external thermal motor protection.

Load Sheave - Five deep-groove pockets fully support the load chain

during operation. Reduces vibration and chain

wear. Provides true vertical lift.

Operating Conditions - Recommended for -4° to +104°F and

humidity of 85% or less. |

|

|

|

SEQ 1

- PHASE DUAL SPEED VFD HOIST - SPECIFICATIONS |

Cap.

(Tons) |

Model

No. |

²Std

Lift

(Ft) |

Push

Button

Cord

L

(ft) |

Hoist¹ 1-Phase 60 Hz |

Load

Chain

Dia.

(mm)

x Chain

Fall Lines |

Net

Wt.

(lbs.) |

Wt.

for

Additional

1 Foot of

Lift (lbs) |

Lifting

Speed² (ft/min) |

Output

(Hp) |

Rated

Current (amps) |

High |

Low |

No

Load

High

Speed |

@115V |

@230V |

1/8 |

SEQ001SD |

10 |

8.2 |

56 |

9.3 |

72 |

0.67 |

10.8 |

5.7 |

5.6

x 1 |

71 |

0.48 |

1/4 |

SEQ003SD |

33 |

5.5 |

43 |

12.1 |

6.4 |

1/2 |

SEQ005SD |

25 |

4.2 |

32 |

1.0 |

14.6 |

7.8 |

75 |

1 |

SEQ010SD |

17 |

3.9 |

22 |

1.3 |

18.7 |

9.9 |

7.1

x 1 |

97 |

0.77 |

|

¹)

Hoists are voltage re-connectable between 115/230V

²) Speeds

are adjustable between low and high speed |

|

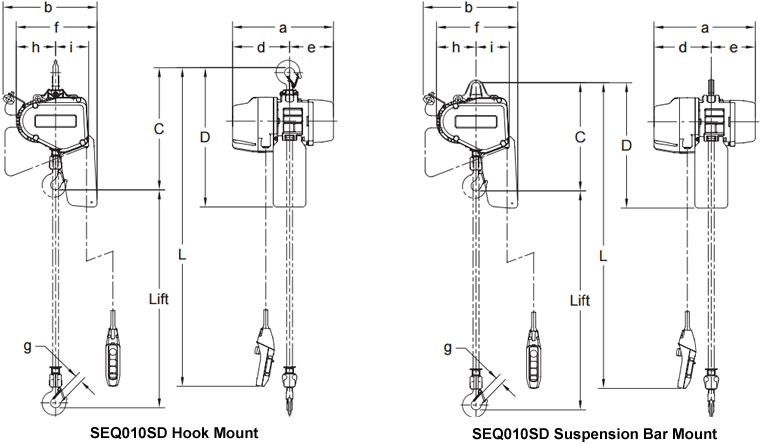

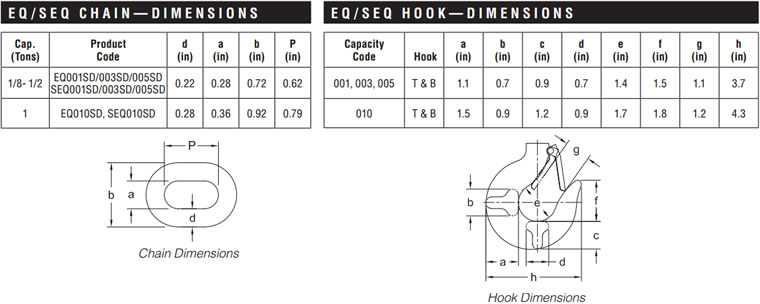

SEQ 1

- PHASE DUAL SPEED VFD HOIST - DIMENSIONS |

Cap.

(Tons) |

Model

No. |

Headroom

C (in) |

D

(in) |

a

(in) |

b

(in) |

d

(in) |

e

(in) |

f

(in) |

g

(in) |

h

(in) |

I

(in) |

Top

Hook |

Susp.

Bar |

Top

Hook |

Susp.

Bar |

1/8 |

SEQ001SD |

17.3 |

15.6 |

21.0 |

19.1 |

16.4 |

14.4 |

9.1 |

7.4 |

11.7 |

1.1 |

5.4 |

5.0 |

1/4 |

SEQ003SD |

1/2 |

SEQ005SD |

18.0 |

16.1 |

1 |

SEQ010SD |

20.7 |

18.3 |

23.5 |

21.1 |

17.0 |

15.9 |

9.6 |

13.1 |

1.2 |

6.1 |

5.6 |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click a Price of the item you wish to purchase. |

|

|

PRICES

FOR EQ SERIES with Plastic Chain Container (Top Hook or Suspension Bar) |

Cap.

(Tons) |

Model

No. |

Lift

Spd

(FPM) |

Price

- Standard Lifts |

Max.

Lift

w/Plastic Chain Cont. |

Load

Chain |

Push

Button

Cord |

Total |

Wt.

10'

lift

(lbs.) |

10' |

15' |

20' |

| 1/8 |

SEQ001SD |

56/9 |

|

|

|

20 |

$20.20 |

$9.30 |

$29.40 |

71 |

| 1/4 |

SEQ003SD |

33/6 |

|

|

|

20 |

71 |

| 1/2 |

SEQ005SD |

25/4 |

|

|

|

20 |

75 |

| 1 |

SEQ010SD |

17/4 |

|

|

|

20 |

$24.20 |

$33.50 |

97 |

|

Standard

pendant hangs approximately 4 ft. above the hoist's fully extended bottom

hook.

For lifts or push button cord lengths other than standard, use 10 ft. base

price plus adders for load chain and push button cord.

For lift and pendant length limitations, consult us.

Standard power supply cord is 15 ft. Extra per ft. is $9.00.

Cable support hangers included for every 5 ft. of power supply cord.

Thermal protection is standard.

*Top hook suspension is standard. Suspension bar is available as an option

at no charge. |

|

PRICES

FOR Optional Longer Lift Canvas Chain Containers |

Cap.

(Tons) |

Model

No. |

Prices |

Maximum

Lift (ft.) |

1/8-1/2 |

EQ1CI1405 |

|

49 |

|

|

SEQP

and SEQG Electric Chain Hoists with Push or Geared Trolleys |

|

|

|

|

|

|

|

|

|

Mounting the

SEQ Series single-phase dual speed

(VFD Control) electric chain hoist to our PT push or GT

geared trolley will create an easy and economical method of

transporting the load. This combination is ideal for work-

stations and infrequent moves. |

|

|

|

|

|

Standard

Hoist Specifications |

|

|

Capacity Range - 1/8 Ton – 1 Ton

Shafts - Standard shafts fit wide range Longer shafts for

wider beams Spacers for easy adjustments

Drop Stops - Standard

Bumpers - Optional

Standard Hand Chain Drop - On geared trolleys 2' less

than lift (longer drops available)

Wheels - All steel. Sealed ball bearings. Fit flat or tapered

beam flange

Standard Hoist Pendant Drop - 4' less than lift (longer

drops available)

Standard Hoist Power Supply Length - 15' (longer lengths

available)

Standard Pendants - 2-button (momentary contacts) with

emergency On/Off (maintained contacts) |

|

|

|

SEQP010SD |

|

SEQG010SD |

|

|

|

|

|

|

|

| Features

and Benefits |

|

Pull-Rotor

Motor Brake - Extremely durable and reliable, this advanced design contains

no brake coil to fail like

conventional disc brakes.

External Motor Fan - Functions to quickly eliminate resistor, motor

and brake heat. This results in improved hoist

duty rating and greatly lengthens brake life. Motor is totally enclosed,

fan cooled (TEFC).

Precision Machined Helical Gears - Immersed in oil bath lubrication

results in quiet, smooth and cool operation.

Chain Container - Durable plastic containers are standard.

Corrosion Resistant Load Chain - Nickel-plated, Grade 80, DIN chain

for superb durability and strength.

Forged Carbon Steel Hooks - Under excessive loads will open gradually

and not fracture. Ball bearings produce

smooth rotation. Bottom hook will swivel 360°. Heavy-duty hook latches

are standard.

Compact Aluminum Body - Die-cast body is lightweight and offers low

headroom – one of the best in the industry.

Paint is electrostatically applied.

Completely Sealed Body- Suitable for both indoor and outdoor applications,

including harsh environments. (Consult

Owner’s Manual for details.) Gaskets throughout the hoist provide for

an IP55 rating.

Variable Frequency Drive (VFD) - Dual speed controls via “under-the-cover”

variable frequency drive for both

single-phase and three-phase hoists. VFD includes count hour meter, load

limiter and no-load high-speed function.

Long Life Friction Clutch - Protects hoist from damage and prevents

overwinding.

Upper/Lower Limit Switch - Low profile upper and lower limit switches

provide excellent headroom.

Unique Chain Guide - Provides quiet and smooth guiding of chain.

Heavy cast iron construction for improved wear

versus stamped steel design offered by many manufacturers.

Durable Push Button Pendant - Easy-to-use, one-handed operation.

Rated IP65. Standard control voltage is 24V.

Strain relief wire is molded to pendant cord for added support and dependability.

E-Stop is standard on all pendants.

Extreme Duty Motor - Increased performance through 30/10-minute duty

rating, H4 classification, Class B insulation,

cooling fins and external thermal motor protection.

Load Sheave - Five deep-groove pockets fully support the load chain

during operation. Reduces vibration and chain

wear. Provides true vertical lift.

Operating Conditions - Recommended for -4° to +104°F and

humidity of 85% or less. |

|

|

|

|

|

SEQ 1

- PHASE DUAL SPEED VFD HOIST WITH PUSH OR GEARED TROLLEY - SPECIFICATIONS |

Cap.

(Tons) |

Model

No. |

Std

Lift

(Ft) |

Push

Button

Cord

L

(ft) |

Hoist¹ 1-Phase 60 Hz |

Flange

Width Adjustability³

B (in) |

Min.³*

Allow

Radius

for

Curve

(in) |

Load

Chain

Dia

(mm) x Chain

Fall

Lines |

Net

Wt.*

(lbs.) |

Wt.

for

Additional

1 Foot

of Lift

(lbs) |

| Lifting

Speed²(ft/min) |

Output

(Hp) |

Rated

Current (amps) |

| High |

Low |

No

Load

High

Speed |

@115V |

@230V |

Standard |

Optional |

| 1/8 |

SEQ(P/G)001SD |

10 |

8.2 |

56 |

9.3 |

72 |

0.67 |

10.8 |

5.7 |

2.28

to

4.00

(2.28

to

5.00) |

4.01

to 8.00

(5.01 to

8.00) or

8.01 to

12.00 |

43.3

(51.2) |

5.6

x 1 |

75

(97) |

0.48 |

75

(99) |

| 12.1 |

6.4 |

79

(104) |

| 1/4 |

SEQ(P/G)003SD |

33 |

5.5 |

43 |

| 25 |

4.2 |

32 |

1.0 |

14.6 |

7.8 |

2.28

to 5.00 |

5.01

to

8.00 or

8.01 to

12.00 |

51.2 |

7.1

x 1 |

108

(123) |

0.77 |

| 1/2 |

SEQ(P/G)005SD |

| 1 |

SEQ(P/G)010SD |

17 |

3.9 |

22 |

1.3 |

18.7 |

9.9 |

|

¹)

Although different voltages are shown, motors are NOT re-connectable and

voltage can NOT be changed due to electrical com-

ponents being voltage specific.

²) Speeds are adjustable between

low and high speed.

³) Figures in parentheses are

data for geared trolley if different than push trolley.

* Minimum Flange Width for curved beam: 1 Ton Push and 1/8

to 1 Ton Geared = 2.87 in. |

|

SEQ 1

- PHASE DUAL SPEED VFD HOIST WITH PUSH TROLLEY - DIMENSIONS |

Cap.

(Tons) |

Model

No. |

Headroom

C (in) |

D

(in) |

a

(in) |

b

(in) |

e

(in) |

g

(in) |

h

(in) |

i

(in) |

j

(in) |

k

(in) |

m

(in) |

n

(in) |

r

(in) |

t

(in) |

| 1/8 |

SEQP001SD |

16.3 |

19.9 |

10.4 |

7.2 |

1.8 |

1.1 |

3.2 |

2.4 |

0.75 |

3.0 |

1.9 |

3.3 |

1.5 |

0.87 |

| 1/4 |

SEQP003SD |

| 1/2 |

SEQP005SD |

16.9 |

| 1 |

SEQP010SD |

19.3 |

22.2 |

11.2 |

9.3 |

2.2 |

1.2 |

4.2 |

2.8 |

0.98 |

3.7 |

2.2 |

4.4 |

2.0 |

0.98 |

|

|

SEQ 1

- PHASE DUAL SPEED VFD HOIST WITH GEARED TROLLEY - DIMENSIONS |

Cap.

(Tons) |

Model

No. |

Headroom

C (in) |

D

(in) |

E

(in) |

a

(in) |

b

(in) |

e

(in) |

g

(in) |

h

(in) |

i

(in) |

j

(in) |

k

(in) |

k¹

(in) |

m

(in) |

n

(in) |

r

(in) |

t

(in) |

u

(in) |

| 1/8 |

SEQG001SD |

16.7 |

20.3 |

10.5 |

20.9 |

9.3 |

13.3 |

1.1 |

4.2 |

2.8 |

1.1 |

3.7 |

4.2 |

2.2 |

4.4 |

2.0 |

0.98 |

7.2 |

| 1/4 |

SEQG003SD |

| 1/2 |

SEQG005SD |

17.3 |

| 1 |

SEQG010SD |

19.3 |

22.2 |

1.2 |

|

|

|

|

|

Order

Online, by Phone, or by E-mail |

|

|

|

~ Add

items to your online shopping cart ~

Click a Price of the item you wish to purchase. |

|

|

PRICES

FOR SEQP SERIES with Plastic Chain Container (Push Trolley) |

Cap.

(Tons) |

Model

No. |

Lift

Std

(FPM) |

Price

- Standard Lifts |

Max.

Lift

w/Plastic Chain Cont. |

Load

Chain |

Push

Button

Cord |

Total |

Wt.

10'

lift

(lbs.) |

10' |

15' |

20' |

1/8 |

SEQP001SD |

56/9 |

|

|

|

20 |

|

|

|

75 |

1/4 |

SEQP003SD |

33/6 |

|

|

|

20 |

75 |

1/2 |

SEQP005SD |

25/4 |

|

|

|

20 |

79 |

1 |

SEQP010SD |

17/4 |

|

|

|

20 |

|

|

108 |

|

|

PRICES

FOR SEQG SERIES with Plastic Chain Container (Geared Trolley) |

Cap.

(Tons) |

Model

No. |

Lift

Std (FPM) |

Price

- Standard Lifts |

Max.

Lift w/Plastic Chain Cont. |

Load

Chain |

Push

Button Cord |

Hand

Chain |

Total |

Wt.

10' lift (lbs.) |

10' |

15' |

20' |

1/8 |

SEQG001SD |

56/9 |

|

|

|

20 |

|

|

|

|

97 |

1/4 |

SEQG003SD |

33/6 |

|

|

|

20 |

99 |

1/2 |

SEQG005SD |

25/4 |

|

|

|

20 |

104 |

1 |

SEQG010SD |

17/4 |

|

|

|

20 |

|

|

123 |

|

Standard

pendant hangs approximately 4 ft. above the hoist's fully extended bottom

hook.

For lifts or push button cord lengths other than standard, use 10 ft. base

price plus adders for load chain and push button cord.

For lift and pendant length limitations, consult us.

Standard power supply cord is 15 ft. Extra per ft. is $9.00

Cable support hangers included for every 5 ft. of power supply cord.

Thermal protection is standard.

Standard trolley hand chain drop is 2 ft. less than lift. (For Geared Trolley

only)

Suspension bar is standard. |

|

PRICES

FOR Manual Trolley Shaft Extenders |

Cap.

(Tons) |

Std.

Flange Width (in.) |

Flange

Width w/Ext. Shaft (in.) |

Prices |

1/8-1/2 |

2.28-4.00 |

4.01-8.00 |

|

8.01-12.00 |

|

*1 |

2.28-5.00 |

5.01-8.00 |

|

8.01-12.00 |

|

|

For

flange ranges beyond this chart, consult Customer Service.

Pricing applies only when purchased with PT or GT trolleys.

*Geared trolleys 1 Ton and under use 1 Ton shaft extender. |

|

Options

and Technical Data |

|

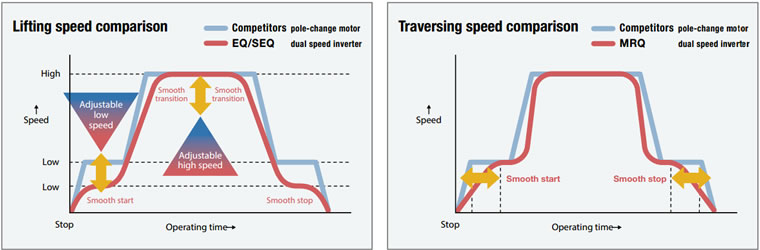

SPEED

COMPARISONS |

|

|

|

| VFD

HOIST CONTROL DESCRIPTIONS |

|

The

dual speed inverter delivers smoother movement than contactor control which

reduces load swing. The inverter

can be programmed to operate specific to the application, resulting in smooth

starts, improved control, improved

positioning accuracy and overall increased productivity. Standard lifting

speed ratio is 6:1. Standard traversing

speed ratio is 6:1 adjustable to 10:1. |

|

A

no-load high-speed function is a standard feature, allowing its hoisting

speed to move 1.3 times faster during no-

load operation. When the no-load condition is detected by the inverter,

this function is activated automatically

switching to high-speed operation, leading to improved work efficiency with

ease and safety. The function is

easily activated (ON/OFF) with the push button control. |

|

EQ,

EQM and SEQ inverter units are well-customized for lifting/traversing applications

including exclusive

software, and are also provided with measures against impact and heat, which

were verified through long-run tests. |

|

|

|

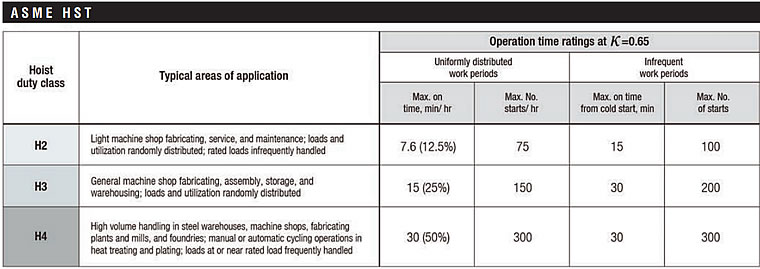

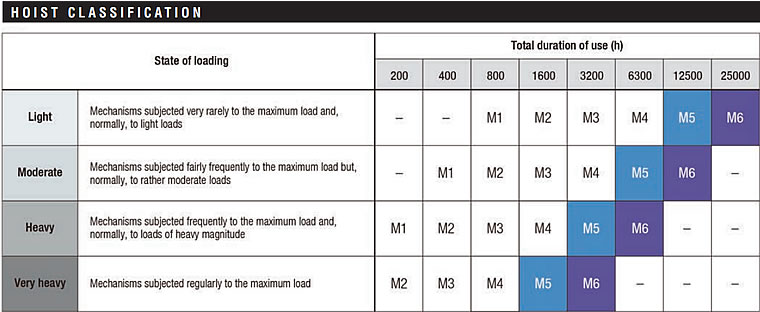

Duty

Classifications |

|

|

| The

grade symbols are identical to those of ASME HST-1M. (Performance standard

for Electric Chain Hoist) |

|

|

| This

classification refers to ISO 4301-1 and applies to the mechanical components

including gears and bearings except for consumable parts. |

|

| COMPLIANCE |

|

These

electric chain hoists are produced to comply with:

• CSA Std. C22.2 No 33-M1984 (R2004), “Construction and Test of

Electrical Cranes and Hoists”

• CSA Std. C22.2 No 14-13, “Industrial Control Equipment”

• CSA Std. C22.2 No. 66.1-06 (R2011), “Low Voltage Transformer-Part

I: General Requirements”

• ANSI/UL508 (17th Edition), “Industrial Control Equipment”

• ANSI/UL508A (First Edition), “Industrial Control Panels”

• ANSI/UL 1004 (First Edition), “Rotating Electrical Machines”

• ANSI/NFPA 70, “National Electrical Code”

• ANSI/ASME B30.16, “Safety Standard—Overhead Hoists (Underhung)”

• ANSI/ASME HST—1M, “Performance Standard for Electric Chain

Hoists” manual and electric-powered trolleys are

produced to comply with the trolley-related requirements of:

• OSHA Section 1910.179 of Title 29, “Occupational Safety and

Health Regulations — Overhead and Gantry Cranes”

• ANSI/ASME B30.11, “Safety Standard—Monorails and Underhung

Cranes”

• ANSI/ASME B30.17, “Safety Standard—Overhead and Gantry

Cranes (Top Running Bridge, Single Girder,

Underhung Hoist)” |

|

|

|

|

|

Harrington SEQ Series Electric

Hoist, SEQP Electric Hoist, SEQG Hoist, Three Phase Dual Speed, Chain

Hoist, Chain Containers,

Electric Chain Hoists, Three Phase, Hook or Suspension Bar Mount, Electric

Chain Hoist with Motorized Trolleys, Electric Chain

Hoists with Push or Geared Trolleys from your source for material handling

equipment. |

Back to Product Category

|