Back to Product Category

WIRE

ROPE 2 LEG BRIDLE SLINGS

|

|

HOW

TO ORDER WIRE ROPE SLINGS |

|

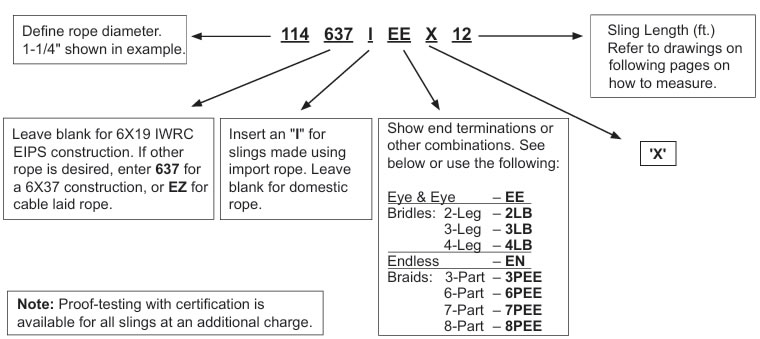

| We

have developed the following wire rope sling code system to help you in

ordering these products. |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click a Price of the item you wish to purchase. |

|

|

Bridle

Slings |

Rope

Dia.

(in.) |

¹Min.

Sling

Length |

Eye

Hook

Cap.

(tons) |

Rated Capacity* (tons) |

Oblong

Link

Stock

Dia. |

Prices |

|

|

|

3' |

4' |

6' |

8' |

6

x

19 |

1/4 |

1' 3" |

1 |

1.1 |

.91 |

.65 |

1/2 |

|

|

|

|

| 5/16 |

1' 6'' |

1 |

1.7 |

1.4 |

1.0 |

1/2 |

|

|

|

|

| 3/8 |

1' 8" |

1 1/2 |

2.5 |

2.0 |

1.4 |

3/4 |

|

|

|

|

| 7/16 |

1' 10" |

2 |

3.4 |

2.7 |

1.9 |

3/4 |

|

|

|

|

| 1/2 |

2' |

3 |

4.4 |

3.6 |

2.5 |

3/4 |

|

|

|

|

| 9/16 |

2' 2" |

4 1/2 |

5.5 |

4.5 |

3.2 |

1 |

|

|

|

|

| 5/8 |

2' 4" |

4 1/2 |

6.8 |

5.5 |

3.9 |

1 |

|

|

|

|

| 3/4 |

2' 9" |

7 |

9.7 |

7.9 |

5.6 |

1 1/4 |

|

|

|

|

| 7/8 |

3' 3" |

11 |

13 |

11 |

7.6 |

1 1/4 |

- |

|

|

|

| 1 |

3' 6" |

11 |

17 |

14 |

9.8 |

1 1/2 |

- |

|

|

|

| 1 1/8 |

4' |

15 |

21 |

17 |

12 |

1 3/4 |

- |

|

|

|

6

x

37

|

1 1/4 |

4' 6" |

15 |

26 |

21 |

15 |

1 3/4 |

- |

- |

|

|

| 1 3/8 |

5' |

22 |

31 |

25 |

18 |

2 |

- |

- |

|

|

| 1 1/2 |

5' 6" |

22 |

37 |

30 |

21 |

2 1/4 |

- |

- |

|

|

| 1 3/4 |

6' 6" |

30 |

49 |

40 |

28 |

2 3/4 |

Upon

Request |

| 2 |

8' |

37 |

63 |

52 |

37 |

2 3/4 |

Upon

Request |

Length

Tolerances (Single Part Wire Rope Slings): Standard length tolerance

is plus or minus two rope diameters,

OR plus or minus 0.5% of the sling length, whichever is greater. The legs

of bridle slings, or matched slings are

normally held to within one rope diameter. |

|

|

|

|

|

|

|

| Other

fittings and latches are available upon request. |

|

|

|

|

|

|

|

|

|

| ¹ Minimum

length based on thimbled eye and eye hook. |

|

|

|

|

|

|

|

|

| * |

|

|

|

|

|

Do

not exceed rated capacities. Sling capacity decreases as the angle from

horizontal decreases.

Slings should not be used at angles of less than 30°. Refer to the Effect

of Angle chart below. |

|

|

|

|

|

|

|

|

|

|

|

|

|

| EFFECT

OF SLING ANGLE |

|

|

|

|

|

|

|

|

|

Using

slings at an angle can become deadly if that angle is not taken into

consideration when selecting the sling to

be used. The tension on each leg of the sling is increased as the angle

of lift, from horizontal, decreases. It is most

desirable for a sling to have a larger angle of lift, approaching 90°.

Lifts with angles of less than 30° from horizontal

are not recommended. If you can measure the angle of lift or the length

and height of the sling as rigged, you can

determine the properly rated sling for your lift. The Increased Tension

method provides the increased tension as a

function of the sling angle. Alternatively, the sling Reduced Capacity method

may be used to determine reduced lift

capacity for any angle. |

|

|

|

|

|

|

|

|

|

INCREASED

TENSION

Determine capacity

of sling needed |

|

REDUCED

CAPACITY

Calculate rating of each sling

rigged at this angle |

|

|

|

|

|

| 1.

Determine the load weight (LW). |

1.

Calculate the reduction factor (RF). |

|

|

|

|

a.

Using the angle from horizontal,

read across the Angle Chart to

the corresponding number of the

Reduction Factor column. |

| 2.

Calculate the Tension Factor [TF]. |

|

|

a.

Determine the sling angle as mea-

sured from the horizontal, and the

corresponding tension factor (TF)

from the effect of angle chart. |

|

|

|

-OR- |

|

|

b.

Divide sling height* (H) by sling

length* (L). |

|

-OR- |

|

|

|

b.

Length* (L) divided by height*

(H) |

|

|

|

|

|

2.

Reduction factor (RF) x the sling’s

rated capacity for the type hitch that

will be used = sling’s reduced rating. |

|

|

|

|

|

|

|

|

|

|

|

|

3.

Determine the share of the load

applied to each sling leg (LW). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4.

Multiply (LW) by (TF) to determine

the sling leg tension. The capacity of

the selected sling or sling leg must

meet the calculated tension value. |

|

|

*Measured

from a common horizontal

plane to the hoisting hook. |

|

|

|

|

|

|

|

|

|

|

|

|

*Measured

from a common horizontal plane

to the hoisting hook. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Effect

of Angle Chart |

|

|

|

|

Tension

Factor (TF) |

Angle From

Horizontal |

Reduction

Factor (RF) |

| 1.000 |

90º |

1.000 |

| 1.004 |

85º |

0.996 |

| 1.015 |

80º |

0.985 |

| 1.035 |

75º |

0.966 |

| 1.064 |

70º |

0.940 |

| 1.104 |

65º |

0.906 |

| 1.155 |

60º |

0.866 |

| 1.221 |

55º |

0.819 |

| 1.305 |

50º |

0.766 |

| 1.414 |

45º |

0.707 |

| 1.555 |

40º |

0.643 |

| 1.742 |

35º |

0.574 |

| 2.000 |

30º |

0.500 |

|

|

|

|

|

|

|

|

|

Example: |

|

|

|

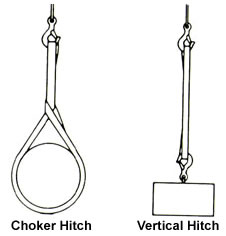

Vertical

Choker rating of each sling:

6,000 lbs.

Measured Length (L) = 6 ft.

Measured Height (H) = 4 ft.

Reduction Factor (RF) = 4 (H) ÷ 6 (L) = .667 |

|

|

|

|

| Example: |

|

|

|

Load

weight = 1,000 lbs.

Rigging - 2 slings in vertical hitch

Lifting Weight (LW) per sling = 500 lbs.

Measured Length (L) = 10 ft.

Measured Height (H) = 5 ft.

Tension Factor (TF) = 10 (L) ÷ 5 (H) = 2.0

Minimum Vertical Rated Capacity required

for this lift = 500 (LW) x 2.0 (TF) = 1000 lbs.

per sling |

|

Sling

capacity decreases as the angle

from horizontal decreases. Sling angles

of less than 30° are not recommended. |

|

|

Reduced

sling rating in this configuration

= .667 |

|

(RF)

x 6,000 lbs. = 4,000 lbs. of lifting

capacity per sling |

|

|

|

|

|

|

|

Wire Rope Bridle Slings,

2, 3, & 4 Leg, Wire Rope Sling, Lift-All, Lifting Slings, 2-Leg Bridle

Sling, Prices include

Thimbled Eyes and Eye Hooks, 3-Leg Bridle Sling, and 4-Leg Bridle Sling

from your source for material handling

equipment. |

Back to Product Category

|