Back to Product Category

|

| FEATURES

AND BENEFITS |

|

|

|

|

|

|

|

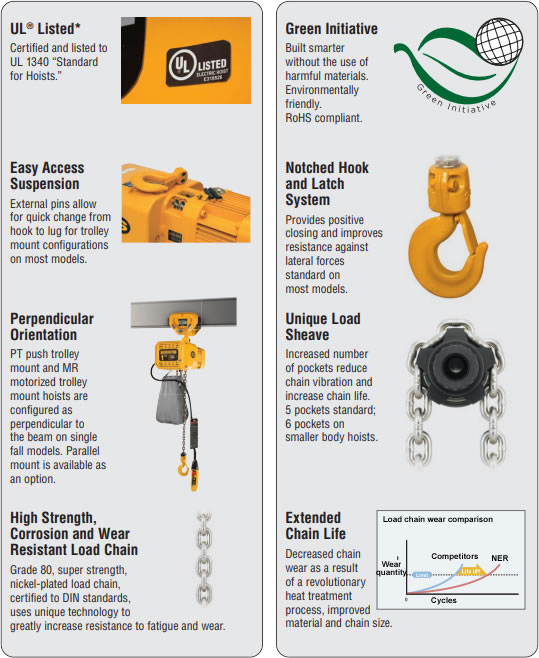

UL® Listed UL® Listed |

|

Standard Count Hour Meter Standard Count Hour Meter |

|

Certified

and listed to UL 1340 “Standard for Hoists.” |

|

|

Records

and displays the number of lowering starts

and hoist on time which is valuable for preventive

maintenance. Integral to VFD on dual speed models. |

|

|

|

|

|

Green Initiative Green Initiative |

|

|

|

Built

smarter without the use of harmful materials. Environmentally friendly.

RoHS compliant. |

|

|

|

|

|

|

|

|

|

Perpendicular Orientation Perpendicular Orientation |

|

|

|

|

|

PT

push trolley mount hoists are configured as

perpendicular to the beam. Parallel mount is available

as an option. Note 020C and 030C models are

parallel mount as standard. |

Notched Hook and Latch System Notched Hook and Latch System |

|

|

|

Provides

positive closing and improves resistance

against lateral forces. |

|

|

|

|

|

|

|

Limit Switches Limit Switches |

|

|

|

|

|

|

|

Dual Speed VFD Dual Speed VFD |

|

Low-profile

upper and lower limit switches are

standard. |

|

|

|

|

Under-the-cover

VFD standard for dual speed hoists.

Speed ratio is 6:1 with adjustability up to 12:1. |

|

|

|

|

|

Extended Chain Life Extended Chain Life |

|

|

|

|

|

|

|

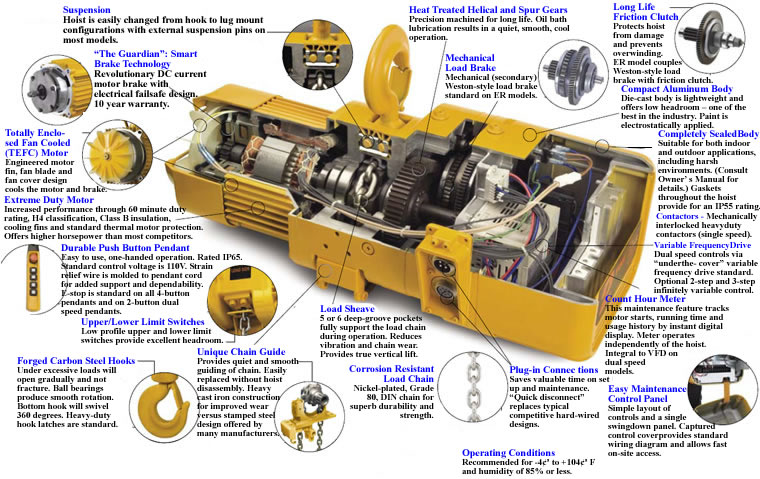

“The Guardian”:

Smart Brake Technology “The Guardian”:

Smart Brake Technology |

|

Decreased

chain wear as a result of a revolutionary heat

treatment process, improved material and chain size. |

|

|

|

|

A

current driven electromagnetic brake does not

release unless the motor is energized. 10 year hoist

brake warranty. |

|

|

|

|

|

Contactors Contactors |

|

|

|

Mechanically

interlocked, heavy-duty contactors on

single speed models. |

|

|

|

|

|

|

|

|

|

Pendant Controls Pendant Controls |

|

|

|

Ergonomic

design for operator comfort. Red button

emergency stop is standard on all 2-button dual speed

pendants. |

|

|

|

|

|

High Air Flow High Air Flow |

|

|

|

Cooler

motor and brake attributed to an engineered

motor fin, fan blade and fan cover design. |

|

|

|

|

|

|

|

|

|

Easy Access Suspension Easy Access Suspension |

|

|

|

|

Unique Load Sheave Unique Load Sheave |

|

|

|

External

pins allow for quick change from hook to

lug for trolley mount configurations on most models. |

|

Increased

number of pockets reduce chain vibration and

increase chain life. 5 pockets standard; 6 pockets on

smaller body hoists. |

|

|

|

|

|

|

|

|

|

High Strength, Corrosion and

Wear Resistant High Strength, Corrosion and

Wear Resistant

Load Chain |

|

|

|

|

Friction Clutch and Load Brake Friction Clutch and Load Brake |

|

|

|

|

Grade

80, super strength, nickel-plated load chain,

certified to DIN standards, uses unique technology

to greatly increase resistance to fatigue and wear |

|

|

Friction

clutch is standard on NER/ER models and

friction clutch with mechanical load brake standard

on ER models. Carbon friction material provides

consistent performance over a wide temperature range. |

|

|

|

|

|

|

|

|

|

|

| Electric

Chain Hoists Enhanced Features |

|

| ELECTRIC

CHAIN HOISTS |

|

|

|

|

|

NERP/ERP

SINGLE SPEED HOIST WITH PUSH TROLLEY - SPECIFICATIONS |

|

Cap.

(tons) |

Product

Code # |

Std.

Lift

(ft) |

Push

Button

Cord L (ft) |

Lifting

Motor 3 Phase 60 Hz. |

Flange

Width

Adjustability

B (in) |

Min.** Allow

Radius for

Curve (in) |

Load Chain

Dia. (mm) x

Chain

Fall Lines |

Net

Wgt.

(lbs) |

Weight

for Addnl.

One Ft.

of Lift (lbs) |

Output

(Hp) |

Rated

Current (amps) |

| @208V |

@460V |

Standard |

Optional |

| 1/8 |

(N)ERP001H |

10 |

8.2 |

0.75 |

3.4 |

1.7 |

2.28 to 4.00

(2.28 to 5.00) |

4.01 to 8.00

(5.01 to 8.00)

OR

8.01 to 12.00 |

43.3

(51.2) |

4.3 x 1 |

71 |

0.28 |

| 1/4 |

(N)ERP003S |

0.75 |

3.4 |

1.7 |

4.3 x 1 |

71 |

0.28 |

| 1/4 |

(N)ERP003H |

1.2 |

4.8 |

2.5 |

6.0 x 1 |

90 |

0.54 |

| 1/2 |

(N)ERP005L |

0.75 |

3.4 |

1.7 |

6.0 x 1 |

82 |

0.54 |

| 1/2 |

(N)ERP005S |

1.2 |

4.8 |

2.5 |

2.28 to 5.00 |

5.01 to 8.00

OR

8.01 to 12.00 |

51.2 |

6.0 x 1 |

90 |

0.54 |

| 1 |

(N)ERP010L |

1.2 |

4.8 |

2.5 |

7.7 x 1 |

121 |

0.89 |

| 1 |

(N)ERP010S |

2.4 |

8.6 |

4.2 |

3.23 to 6.02 |

6.03

to 12.00 |

59.1 |

7.7 x 1 |

137 |

0.89 |

| 1 1/2 |

(N)ERP015S |

2.4 |

8.6 |

4.2 |

10.2 x 1 |

187 |

1.6 |

| 2 |

(N)ERP020C |

1.2 |

4.8 |

2.5 |

7.7 x 2 |

161 |

1.8 |

| 2 |

(N)ERP020L |

2.4 |

8.6 |

4.2 |

10.2 x 1 |

190 |

1.6 |

| 2 |

(N)ERP020S |

4.7 |

16.4 |

7.9 |

10.2 x 1 |

231 |

1.6 |

| 2 1/2 |

(N)ERP025S |

4.7 |

16.4 |

7.9 |

66.9 |

11.2 x 1 |

280 |

1.9 |

| 3 |

(N)ERP030L* |

4.7 |

18.3 |

9.2 |

12.5 x 1 |

311 |

2.3 |

| 3 |

(N)ERP030C |

9.2 |

4.7 |

16.4 |

7.9 |

10.2 x 2 |

284 |

3.2 |

| 5 |

(N)ERP050L |

4.7 |

16.4 |

7.9 |

3.94 to 7.02 |

7.03 to 12.00 |

90.6 |

11.2 x 2 |

399 |

3.8 |

|

| SEE

BOTTOM TABLE BELOW FOR PRICING |

|

|

Figures

in parentheses are data for geared trolley.

*The NERP030L listed are the previous hoist models.

**Minimum Flange Width for curved beam: 1 Ton Push and 1/8 to 1 Ton Geared

= 2.87 in. 3 Ton Push or Geared = 3.50 in |

|

|

|

|

|

|

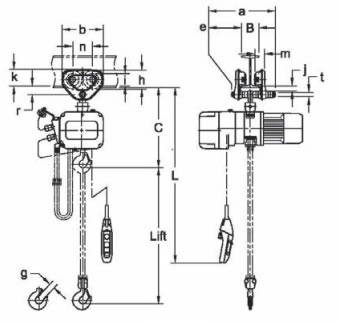

NERP/ERP

SINGLE SPEED HOIST WITH PUSH TROLLEY - DIMENSIONS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DIMENSIONS

(inches) |

Cap.

(Tons) |

Product

Code |

Headroom

C

(in) |

a

(in) |

b

(in) |

e

(in) |

g

(in) |

h

(in) |

i

(in) |

j

(in) |

k

(in) |

m

(in) |

n

(in) |

r

(in) |

t

(in) |

| 1/8 |

(N)ERP001H |

15.6 |

8.0 |

7.2 |

1.8 |

1.1 |

3.2 |

2.36 |

0.8 |

3.0 |

1.9 |

3.3 |

1.5 |

0.87 |

| 1/4 |

(N)ERP003S |

15.6 |

8.0 |

7.2 |

1.8 |

1.1 |

3.2 |

2.36 |

0.8 |

3.0 |

1.9 |

3.3 |

1.5 |

0.87 |

| 1/4 |

(N)ERP003H |

16.3 |

8.0 |

7.2 |

1.8 |

1.1 |

3.2 |

2.36 |

0.8 |

3.0 |

1.9 |

3.3 |

1.5 |

0.87 |

| 1/2 |

(N)ERP005L |

16.3 |

8.0 |

7.2 |

1.8 |

1.1 |

3.2 |

2.36 |

0.8 |

3.0 |

1.9 |

3.3 |

1.5 |

0.87 |

| 1/2 |

(N)ERP005S |

16.3 |

8.0 |

7.2 |

1.8 |

1.1 |

3.2 |

2.36 |

0.8 |

3.0 |

1.9 |

3.3 |

1.5 |

0.87 |

| 1 |

(N)ERP010L |

18.5 |

9.8 |

9.3 |

2.2 |

1.2 |

4.2 |

2.8 |

1.1 |

3.7 |

2.2 |

4.4 |

2.0 |

0.98 |

| 1 |

(N)ERP010S |

18.5 |

9.8 |

9.3 |

2.2 |

1.2 |

4.2 |

2.8 |

1.1 |

3.7 |

2.2 |

4.4 |

2.0 |

0.98 |

| 1 1/2 |

(N)ERP015S |

22.4 |

11.8 |

11.0 |

2.7 |

1.3 |

5.0 |

3.35 |

1.3 |

4.4 |

2.8 |

5.2 |

2.4 |

1.26 |

| 2 |

(N)ERP020C |

27.4 |

11.8 |

11.0 |

2.7 |

1.5 |

5.0 |

3.35 |

1.3 |

4.4 |

2.8 |

5.2 |

2.4 |

1.26 |

| 2 |

(N)ERP020L |

25 |

11.8 |

11.0 |

2.7 |

1.5 |

5.0 |

3.35 |

1.3 |

4.4 |

2.8 |

5.2 |

2.4 |

1.26 |

| 2 |

(N)ERP020S |

25.6 |

11.8 |

11.0 |

2.7 |

1.5 |

5.0 |

3.35 |

1.3 |

4.4 |

2.8 |

5.2 |

2.4 |

1.26 |

| 2 1/2 |

(N)ERP025S |

26.8 |

12.6 |

12.8 |

3.1 |

1.5 |

5.8 |

3.94 |

1.4 |

5.3 |

3.1 |

6.0 |

2.7 |

1.42 |

| 3 |

(N)ERP030L* |

27.8 |

12.6 |

12.8 |

3.1 |

1.7 |

5.8 |

3.94 |

1.4 |

5.3 |

3.1 |

6.0 |

2.7 |

1.42 |

| 3 |

(N)ERP030C |

32.7 |

12.6 |

12.8 |

3.1 |

1.8 |

5.8 |

3.94 |

1.4 |

5.3 |

3.1 |

6.0 |

2.7 |

1.42 |

| 5 |

(N)ERP050L |

35.4 |

11.7 |

15.7 |

2.1 |

1.9 |

6.7 |

4.65 |

1.8 |

5.6 |

3.2 |

7.0 |

3.4 |

2.13 |

|

| *The

NERP030L listed is the previous hoist model. |

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click a Price of the item you wish to purchase. |

|

|

|

PRICING

FOR NERP SINGLE SPEED HOIST WITH PUSH TROLLEY |

Cap.

(Tons) |

Product Code |

Lift Spd.

(FPM) |

Price

- Standard Lifts |

Max. Lift

w/Canvas

Chain Cont. |

Chain

Cont.

Adder |

Load Chain |

Push

Button

Cord |

Total |

| 10' |

15' |

20' |

| 1/8 |

NERP001H |

55 |

|

|

|

50 |

|

|

|

|

| 1/4 |

NERP003S |

36 |

|

|

|

50 |

| 1/4 |

NERP003H |

53 |

|

|

|

50 |

|

|

|

| 1/2 |

NERP005L |

15 |

|

|

|

50 |

| 1/2 |

NERP005S |

29 |

|

|

|

50 |

| 1 |

NERP010L |

14 |

|

|

|

50 |

|

|

|

| 1 |

NERP010S |

28 |

|

|

|

50 |

| 1 1/2 |

NERP015S |

18 |

|

|

|

60 |

|

|

|

| 2 |

NERP020C |

7 |

|

|

|

26 |

|

|

|

| 2 |

NERP020L |

14 |

|

|

|

60 |

|

|

|

| 2 |

NERP020S |

28 |

|

|

|

60 |

| 2 1/2 |

NERP025S |

22 |

|

|

|

40 |

|

|

| 3 |

NERP030L* |

16 |

|

|

|

26 |

|

|

| 3 |

NERP030C |

17 |

|

|

|

20 |

|

|

| 5 |

NERP050L |

11 |

|

|

|

20 |

|

|

|

Std.

pendant hangs approximately 4 ft. above the hoist's fully extended bottom

hook. For lifts or push button cord lengths other than

standard, use 10 ft. base price plus adders for load chain and push button

cord.

Hoists may require a chain container based on the capacity, lift or suspension,

consult us.

Lifts larger than stated "Max. Lift w/Canvas Chain Cont." may

require steel chain container for balance, consult us.

Standard power supply cord 1/8 - 5 Ton is 15 ft. For optional 30 ft. length

add $131.98.

Standard power supply above 5 Ton is 30 ft

Extra per ft. over 30 ft. is $8.80.

No price deduction for shorter lengths.

Cable support hangers included for every 5 ft. of power supply cord. Thermal

motor protection is standard.

*The NERP030L listed is the previous hoist model. |

|

PRICING

FOR ERP SINGLE SPEED HOIST WITH PUSH TROLLEY |

| Cap. (Tons) |

Product Code |

Lift Spd.

(FPM) |

Price

- Standard Lifts |

Max. Lift

w/Canvas

Chain Cont. |

Chain

Cont.

Adder |

Load

Chain |

Push

Button

Cord |

Total |

| 10' |

15' |

20' |

| 1/8 |

ERP001H |

55 |

|

|

|

50 |

|

|

|

|

| 1/4 |

ERP003S |

36 |

|

|

|

50 |

| 1/4 |

ERP003H |

53 |

|

|

|

50 |

|

|

|

| 1/2 |

ERP005L |

15 |

|

|

|

50 |

| 1/2 |

ERP005S |

29 |

|

|

|

50 |

| 1 |

ERP010L |

14 |

|

|

|

50 |

|

|

|

| 1 |

ERP010S |

28 |

|

|

|

50 |

| 1 1/2 |

ERP015S |

18 |

|

|

|

60 |

|

|

|

| 2 |

ERP020C |

7 |

|

|

|

26 |

|

|

|

| 2 |

ERP020L |

14 |

|

|

|

60 |

|

|

|

| 2 |

ERP020S |

28 |

|

|

|

60 |

| 2 1/2 |

ERP025S |

22 |

|

|

|

40 |

|

|

| 3 |

ERP030C |

17 |

|

|

|

20 |

|

|

| 5 |

ERP050L |

11 |

|

|

|

20 |

|

|

|

Std.

pendant hangs approximately 4 ft. above the hoist's fully extended bottom

hook. For lifts or push button cord lengths other than

standard, use 10 ft. base price plus adders for load chain and push button

cord.

Hoists may require a chain container based on the capacity, lift or suspension,

consult us.

Lifts larger than stated "Max. Lift w/Canvas Chain Cont." may

require steel chain container for balance, consult us.

Standard power supply cord 1/8 - 5 Ton is 15 ft. For optional 30 ft. length

add $131.98.

Standard power supply above 5 Ton is 30 ft

Extra per ft. over 30 ft. is $8.80.

No price deduction for shorter lengths.

Cable support hangers included for every 5 ft. of power supply cord. Thermal

motor protection is standard. |

|

PRICING

FOR MANUAL TROLLEY SHAFT EXTENDERS |

|

Cap.

(Tons) |

Std. Flange

Width (in.) |

Flange Width

w/Ext. Shaft (in.) |

Price |

| 1/8 - 1/2 |

2.28-4.00 |

4.01-8.00 |

|

| 8.01-12.00 |

|

| 1* |

2.28-5.00 |

5.01-8.00 |

|

| 8.01-1200 |

|

| 1 1/2 - 2 |

3.23-6.02 |

6.03-12.00 |

|

| 2 1/2 - 3 |

3.23-6.02 |

6.03-12.00 |

|

| 5 |

4.92-7.02 |

7.03-12.00 |

|

|

For

flange ranges beyond this chart, consult us.

Pricing applies only when purchased with PT or GT trolleys.

*Geared trolleys 1 Ton and under use 1 Ton shaft extender. |

|

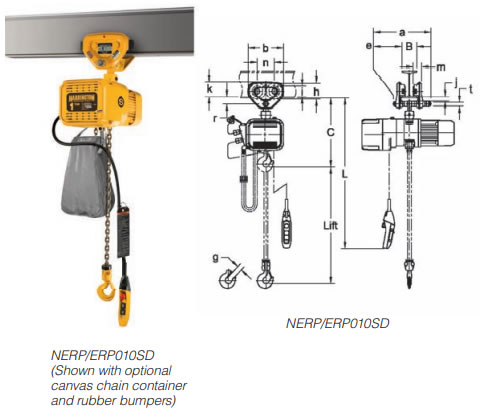

NERP/ERP

DUAL SPEED HOIST WITH PUSH TROLLEY |

|

|

|

|

NERP/ERP

DUAL SPEED HOIST WITH PUSH TROLLEY - SPECIFICATIONS |

|

Cap.

(tons) |

Product

Code # |

Std.

Lift

(ft) |

Push

Button

Cord L (ft) |

Lifting

Motor 3 Phase 60 Hz. |

Flange

Width

Adjustability

B (in) |

Min.** Allow

Radius for

Curve (in) |

Load Chain

Dia. (mm) x

Chain

Fall Lines |

Net

Wgt.

(lbs) |

Weight

for Addnl.

One Ft.

of Lift (lbs) |

Output

(Hp) |

Rated

Current (amps) |

| @208V |

@460V |

Standard |

Optional |

| 1/8 |

(N)ERP001HD |

10 |

8.2 |

0.75 |

3.6 |

1.8 |

2.28 to 4.00

(2.28 to 5.00) |

4.01 to 8.00

(5.01 to 8.00)

OR

8.01 to 12.00 |

43.3 (51.2) |

4.3 x 1 |

71 (88) |

0.28 (.94) |

| 1/4 |

(N)ERP003SD |

0.75 |

3.6 |

1.8 |

4.3 x 1 |

71 (88) |

0.28 (.94) |

| 1/4 |

(N)ERP003HD |

1.2 |

5.1 |

2.7 |

6.0 x 1 |

90 (108) |

0.54 (1.1) |

| 1/2 |

(N)ERP005LD |

0.75 |

3.6 |

1.8 |

6.0 x 1 |

82 (99) |

0.54 (1.1) |

| 1/2 |

(N)ERP005SD |

1.2 |

5.1 |

2.7 |

2.28 to 5.00 |

5.01 to 8.00

OR

8.01 to 12.00 |

51.2 |

6.0 x 1 |

90 (108) |

0.54 (1.1) |

| 1 |

(N)ERP010LD |

1.2 |

5.1 |

2.7 |

7.7 x 1 |

121 (130) |

0.89 (1.6) |

| 1 |

(N)ERP010SD |

2.4 |

9.1 |

4.5 |

3.23 to 6.02 |

6.03

to 12.00 |

59.1 |

7.7 x 1 |

137 (146) |

0.89 (1.6) |

| 1 1/2 |

(N)ERP015SD |

2.4 |

9.1 |

4.5 |

10.2 x 1 |

187 (196) |

1.6 (2.2) |

| 2 |

(N)ERP020CD |

1.2 |

5.1 |

2.7 |

7.7 x 2 |

161 (172) |

1.8 (2.4) |

| 2 |

(N)ERP020LD |

2.4 |

9.1 |

4.5 |

10.2 x 1 |

190 (198) |

1.6 (2.2) |

| 2 |

(N)ERP020SD |

4.7 |

17.3 |

8.3 |

10.2 x 1 |

231 (240) |

1.6 (2.2) |

| 2 1/2 |

(N)ERP025SD |

4.7 |

17.3 |

8.3 |

66.9 |

11.2 x 1 |

280 (289) |

1.9 (2.5) |

| 3 |

(N)ERP030LD* |

4.7/1.6 |

19.6/9.4 |

9.8/4.7 |

12.5 x 1 |

311 (322) |

2.3 (2.9) |

| 3 |

(N)ERP030CD |

9.2 |

4.7 |

17.3 |

8.3 |

10.2 x 2 |

284 (293) |

3.2 (3.8) |

| 5 |

(N)ERP050LD |

4.7 |

17.3 |

8.3 |

3.94 to 7.02 |

7.03 to 12.00 |

90.6 |

11.2 x 2 |

399 (415) |

3.8 (4.4) |

|

| SEE

BOTTOM TABLE BELOW FOR PRICING |

|

|

*The

NERP030LD listed are the previous hoist models.

**Minimum Flange Width for curved beam: 1 Ton Push and 1/8 to 1 Ton Geared

= 2.87 in. 3 Ton Push or Geared = 3.50 in |

|

NERP/ERP

DUAL SPEED HOIST WITH PUSH TROLLEY - DIMENSIONS |

|

|

|

DIMENSIONS

(inches) |

Cap.

(Tons) |

Product

Code |

Headroom

C

(in) |

a

(in) |

b

(in) |

e

(in) |

g

(in) |

h

(in) |

i

(in) |

j

(in) |

k

(in) |

m

(in) |

n

(in) |

r

(in) |

t

(in) |

| 1/8 |

(N)ERP001HD |

15.6 |

8.0 |

7.2 |

1.8 |

1.1 |

3.2 |

2.36 |

0.8 |

3.0 |

1.9 |

3.3 |

1.5 |

0.87 |

| 1/4 |

(N)ERP003SD |

15.6 |

8.0 |

7.2 |

1.8 |

1.1 |

3.2 |

2.36 |

0.8 |

3.0 |

1.9 |

3.3 |

1.5 |

0.87 |

| 1/4 |

(N)ERP003HD |

16.3 |

8.0 |

7.2 |

1.8 |

1.1 |

3.2 |

2.36 |

0.8 |

3.0 |

1.9 |

3.3 |

1.5 |

0.87 |

| 1/2 |

(N)ERP005LD |

16.3 |

8.0 |

7.2 |

1.8 |

1.1 |

3.2 |

2.36 |

0.8 |

3.0 |

1.9 |

3.3 |

1.5 |

0.87 |

| 1/2 |

(N)ERP005SD |

16.3 |

8.0 |

7.2 |

1.8 |

1.1 |

3.2 |

2.36 |

0.8 |

3.0 |

1.9 |

3.3 |

1.5 |

0.87 |

| 1 |

(N)ERP010LD |

18.5 |

9.8 |

9.3 |

2.2 |

1.2 |

4.2 |

2.8 |

1.1 |

3.7 |

2.2 |

4.4 |

2.0 |

0.98 |

| 1 |

(N)ERP010SD |

18.5 |

9.8 |

9.3 |

2.2 |

1.2 |

4.2 |

2.8 |

1.1 |

3.7 |

2.2 |

4.4 |

2.0 |

0.98 |

| 1 1/2 |

(N)ERP015SD |

22.4 |

11.8 |

11.0 |

2.7 |

1.3 |

5.0 |

3.35 |

1.3 |

4.4 |

2.8 |

5.2 |

2.4 |

1.26 |

| 2 |

(N)ERP020CD |

27.4 |

11.8 |

11.0 |

2.7 |

1.5 |

5.0 |

3.35 |

1.3 |

4.4 |

2.8 |

5.2 |

2.4 |

1.26 |

| 2 |

(N)ERP020LD |

25 |

11.8 |

11.0 |

2.7 |

1.5 |

5.0 |

3.35 |

1.3 |

4.4 |

2.8 |

5.2 |

2.4 |

1.26 |

| 2 |

(N)ERP020SD |

25.6 |

11.8 |

11.0 |

2.7 |

1.5 |

5.0 |

3.35 |

1.3 |

4.4 |

2.8 |

5.2 |

2.4 |

1.26 |

| 2 1/2 |

(N)ERP025SD |

26.8 |

12.6 |

12.8 |

3.1 |

1.5 |

5.8 |

3.94 |

1.4 |

5.3 |

3.1 |

6.0 |

2.7 |

1.42 |

| 3 |

(N)ERP030LD* |

27.8 |

12.6 |

12.8 |

3.1 |

1.7 |

5.8 |

3.94 |

1.4 |

5.3 |

3.1 |

6.0 |

2.7 |

1.42 |

| 3 |

(N)ERP030CD |

32.7 |

12.6 |

12.8 |

3.1 |

1.8 |

5.8 |

3.94 |

1.4 |

5.3 |

3.1 |

6.0 |

2.7 |

1.42 |

| 5 |

(N)ERP050LD |

35.4 |

11.7 |

15.7 |

2.1 |

1.9 |

6.7 |

4.65 |

1.8 |

5.7 |

3.2 |

7.0 |

3.4 |

2.13 |

|

| *The

NERP030L listed is the previous hoist model. Speed ration is 6:1 with adjustability

up to 12:1. |

|

NER Dual Speed

Electric Chain Hoists

Smart Limit Option |

Our

unique Smart Limit is available on NER three phase dual speed electric chain

hoists. Unlike geared limit

switches, this Smart Limit allows the user to add upper and lower limit

positions that can be conveniently

programmed at the pendant. The soft stop feature within the Smart Limit

slows the hook down as it approaches

each limit for smooth and very precise load positioning. |

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click a Price of the item you wish to purchase. |

|

|

|

PRICING

FOR Electric Chain Hoists - Three Phase |

| NER/ER

- 6:1 Standard Hoist Adjustable to 12:1 Dual Speed and Smart Limit Adders

(VFD Control) |

|

| Dual Speed Hoist Price (NER/ER SERIES) |

Smart Limit (NER Series) |

Cap.

(Tons) |

Product Code |

Lift Spd.

(FPM) |

Extra $ |

Net Weight

Adder (lbs) |

Extra $ |

| 1/8 |

NER001HD |

55/9 |

|

11 |

|

| 1/4 |

NER003SD |

36/6 |

|

11 |

|

| 1/4 |

NER003HD |

53/9 |

|

17 |

|

| 1/2 |

NER005LD |

15/2.5 |

|

14 |

|

| 1/2 |

NER005SD |

29/5 |

|

17 |

|

| 1 |

NER010LD |

14/2.5 |

|

18 |

|

| 1 |

NER010SD |

28/4.5 |

|

18 |

|

| 1 1/2 |

NER015SD |

18/3 |

|

16 |

|

| 2 |

NER020CD |

7/1 |

|

16 |

|

| 2 |

NER020LD |

14/2.5 |

|

47 |

|

| 2 |

NER020SD |

28/4.5 |

|

47 |

|

| 2 1/2 |

NER025SD |

22/3.5 |

|

46 |

|

| 3 |

NER030LD* |

17/6 |

|

44 |

- |

| 3 |

NER030CD |

17/3 |

|

51 |

|

| 5 |

NER050LD |

11/2 |

|

46 |

|

|

|

*The

NER/ER030LD listed is the previous hoist model (2 speed hoist & trolley

via contactor control; trolley via VFD.

Consult us for VFD packages). |

Specify

hoist model and voltage. VFD Control is not reconnectable voltage.

Retrofit Smart Limit to existing NER Series hoist

is not available.

Smart Limit can only be added to NER dual speed (VFD Control) units.

Infinitely Variable Speed - VFD Adder (Add to Dual Speed Prices)

• 2-Step infinitely variable - add $132.02 for each infinitely variable directional axis.

• 3-Step infinitely variable - add $462.10 for each infinitely variable directional axis. |

|

| (N)ER

VFD HOIST CONTROL DESCRIPTIONS |

|

Dual

Speed Control

Uses a 2-step button and a VFD to control the speed. Pressing the button

to the first step causes the hoist to

accelerate smoothly to the low speed. Pressing the button to the second

step causes the hoist to accelerate

smoothly to the high speed. Releasing the button from the second step to

the first step causes the hoist to

smoothly decelerate to the low speed. Releasing the button completely from

any step causes the hoist to

decelerate quickly to a stop with the brake holding the load. |

|

2–Step

Infinitely Variable Control

Uses a 2-step button and a VFD to control the speed. The acceleration rate

can be changed by changing

parameters in the VFD. The 2-Step Infinitely Variable differs from Dual

Speed Control in that when releasing

the button from the second step to the first step it will maintain whatever

the speed was at the instant before

the button arrived at the first step. This allows you to hold any speed

between the low and the high speed.

If the hoist is operating at a speed that is less than high speed, and you

wish it to operate at a faster speed,

press the button to the second step to accelerate the hoist. When you reach

the desired speed, release the

button to the first step. Note that there is no deceleration function other

than completely releasing the button. |

|

3–Step

Infinitely Variable Control

Uses a 3-step button and a VFD to control the speed. This control is similar

to the 2-Step Infinitely Variable

Control with the added feature of a deceleration function. If the hoist

is operating at a particular speed and

you wish it to operate at a faster speed, press the button to the third

step to accelerate. When you reach the

desired speed, release the button to the second step to maintain that speed.

If the hoist is operating at a particular

speed and you want it to operate at a slower speed, release the button to

the first step to decelerate. When you

reach the desired speed, press the button to the second step to maintain

that speed. |

|

Harrington NERP Single Speed

Hoist, Push Trolley, Electric Chain Hoists, Chain Hoist, Three Phase,

Motor Brake, SNER Single

Phase Chain Hoists, Dust-Resistant, Water-Jet-Resistant, Chain Containers,

and Dual Speed Models from your source for material

handling equipment. |

Back to Product Category

|