Back to Product Category

ELF

SERIES LONG STROKE BALANCERS

|

|

|

|

|

|

|

|

|

|

ELF-3 |

ELF-15 |

|

ELF-22 |

|

ELF-50 |

|

ELF-70 |

|

|

|

|

|

|

|

|

ENDO

Long Stroke Spring Balancers are designed for high ceiling applications.

They provide true "zero gravity"

tool holding with no drifting or strain. The tapered drums and quality springs

and bearings provides smooth cable

travel throughout the stroke. Tension adjustment is easy and precise. The

ELF models offer both the automatic brake

and the manual drum safety lock. In the event that a spring breaks, an automatic

centrifugal brake engages and locks,

preventing damage to the tool. With the manual lock engaged, the drum will

not rotate. This allows for easy change

out or maintenance of tools. Choose the correct balancer based on the total

weight to be balanced (tool and all

accessories) and stroke requirements. Try to utilize the upper range of

the balancer capacity ratings. |

|

|

|

|

|

|

|

|

ELF Series

Balancers Feature |

• Cast

aluminum case and a forged swivel hook.

• Automatic Safety Brake

• Manual Drum Safety Lock

• Exclusive 18 month warranty. |

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Model No. of the item you wish

to purchase. |

|

|

PRICES |

Model

No. |

Capacity

Range (lbs) |

Cable

Travel (ft) |

Cable

Dia (in) |

Wt

(lbs) |

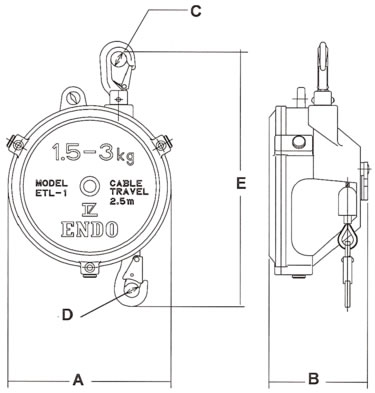

A

in. |

B

in. |

C

in. |

D

in. |

E

in. |

Prices |

| ELF-3 |

3.3 to 6.6 |

8.2 |

0.16 |

9 |

7.8 |

4.7 |

0.75 |

0.59 |

13.7 to 112.1 |

$935.48 |

| ELF-5 |

5.5 to 11 |

8.2 |

0.16 |

9.3 |

7.8 |

4.7 |

0.75 |

0.59 |

13.7 to 112.1 |

$955.80 |

| ELF-9 |

11 to 19.8 |

8.2 |

0.16 |

10.4 |

7.8 |

4.7 |

0.75 |

0.59 |

13.7 to 112.1 |

$1,042.23 |

| ELF-15 |

19.8 to

33.1 |

8.2 |

0.19 |

22 |

9.1 |

8.4 |

1.18 |

0.87 |

17.3 to 115.7 |

$1,609.12 |

| ELF-22 |

33.1 to

48.5 |

8.2 |

0.19 |

22.5 |

9.1 |

8.4 |

1.18 |

0.87 |

17.3 to 115.7 |

$1,759.10 |

| ELF-30 |

48.5 to

66.1 |

8.2 |

0.19 |

24.3 |

9.1 |

8.4 |

1.18 |

0.87 |

17.3 to 115.7 |

$2,158.17 |

| ELF-40 |

66.1 to

88.2 |

8.2 |

0.19 |

30.9 |

9.9 |

9 |

1.18 |

0.87 |

17.7 to 116.1 |

$2,247.13 |

| ELF-50 |

88.2 to

110.2 |

8.2 |

0.19 |

32 |

9.9 |

9 |

1.18 |

0.87 |

17.7 to 116.1 |

$2,684.40 |

| ELF-60 |

110.2 to

132.3 |

8.2 |

0.19 |

37.5 |

9.9 |

10.2 |

1.18 |

0.87 |

17.7 to 116.1 |

$2,793.70 |

| ELF-70 |

132.3 to

154.3 |

8.2 |

0.19 |

39.7 |

9.9 |

10.2 |

1.18 |

0.87 |

17.7 to 116.1 |

$2,930.95 |

|

|

|

|

Balancer

Safety Features |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Plug-in

Cable Set |

|

|

|

|

|

|

Fall Arrest

System |

|

|

|

|

|

For

easy cable replacement |

|

|

|

|

|

|

|

Prevents

tool from

dropping in the unlikely

event that a spring

breaks |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Safety

Spring Canister |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

For

safe spring

replacement |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| See

chart above for measurements |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Features

and Benefits |

|

|

|

|

|

|

ENDO

Spring Balancers are a valuable addition to your

assembly line. They support heavy tools with cable tension

equal to the weight of the suspended tools, which makes

them seem virtually "weightless". As the tool is repositioned

the balancer extends or retracts the support cable to follow

the tool's movements. Constant tension on the cable is

accomplished with a spring motor and a tapered drum. The

assembler has the flexibility to reposition the tool, while

experiencing comfortable operation and less fatigue. Similar

to a Balancer is the Retractor, which does not have a

tapered drum. The tension on the cable increases as the

cable is extended |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tension

Gauge |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Worm

Gear System

Turn clockwise to

increase tension,

counter-clockwise to

decrease tension |

|

|

|

|

|

|

|

Lets

operator see tension

setting |

|

|

|

|

| Advantages

of Using an ENDO Spring Balancer: |

|

|

|

|

|

|

|

|

•

Suspend tools in assembly lines or other work areas

• Help the assembler with repetitive tasks such as

installing fasteners: screws, nuts, bolts, etc.

• Hold fixtures, tools, welding guns, and similar

equipment

• Improves efficiency and diminishes worker fatigue

• Stabilizes tool positioning and contributes to work

accuracy

• Contributes to a safer working environment

• Keeps fixtures, tools, and welding guns off of the floor

and clean.

• Eliminates the need to separately power the balancer |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Secondary

Support Hangers |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Drum Lock

System |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

On

top and bottom

to accommodate

safety chain |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Available

to lock the

spool while replacing

a tool |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Application

Guidelines |

•

Size the balancer to carry the total weight to be balanced - tool plus all

accessories - and stroke (maximum to

minimum height) required.

• Size to the upper end of the capacity range of the balancer when

possible.

• Always attach secondary support cable(s) to the eyelet provided for

additional safety.

• Balancers are normally hung vertically and the rope is pulled out

vertically. To prevent the rope from wearing on the

guide, the rope should not be pulled out at an angle to the

balancer body. The balancer can also be mounted

horizontally, however a pulley system must be employed to guide

the rope straight out of the balancer then down to

the tool. Again, care must be taken to prevent the rope from

wearing on the guide. A trolley and rail system can be

used to help the balancer adjust to changing angles.

• If multiple balancers are used in close together, install them at

staggered heights to keep them from hitting each other

• The spring tension is factory preset to the mid-range of the rated

capacity. To adjust the tension turn the worm gear

or spindle clockwise to increase the tension and counterclockwise

to decrease the tension. |

|

Long Stroke Balancers, Balancer,

Zero Gravity Tool Balancer, Tool Balancer, Auto Brake Balancers, Tool

Positioner,

Fall Arrest System Balancer, Spring Balancer, Tool Retractors, and Long

Stroke Spring Balancers from your source

for material handling equipment. |

Back to Product Category

|