ZIG-ZAG

|

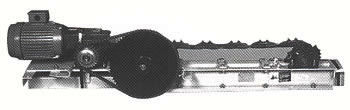

NO. 2035 CONTINUOUS OVERHEAD POWER CHAIN CONVEYOR

|

|

|

|

|

The Original Enclosed Track Conveyor

|

|

|

|

Zig-Zag conveyor is constructed of standard, modular

components that guarantee easy installation, modification

and maintenance. Standard components also guarantee

quick accessibility . |

|

|

|

|

|

|

|

|

|

|

NO. 2035 ZIG-ZAG CONVEYORS

|

|

|

|

|

|

|

|

|

|

FEATURES:

|

| ELEVEN STANDARD COMPONENTS |

|

VERTICAL CHAIN WHEELS ON 6" CENTERS |

| • Straight Track, 3/16" thick, stocked in 10' lengths |

|

• Spread the same amount of load over more wheels |

| • Welding Jig |

|

• Reduce the point loading on track and reduce wear |

| • Horizontal Curves, 3/16" thick, 90°, flame hardened |

|

CAPACITIES |

| • Top Vertical Curves, 3/16" thick, 90°, flame hardened |

|

• 75 lbs. per load pin |

| • Bottom Vertical Curves, 3/16" thick, 90°, flame hardened |

• Standard drive packages up to 750 lb. chain pull |

| • Conveyor Chain, 6" pitch |

|

|

|

| • Take-up Assembly |

|

|

|

| • Inspection Section |

|

|

|

| • Chain Oiler |

|

|

|

| • Standard Drive Packages |

|

|

|

| • Load Pendant Attachments |

|

|

|

Click the button of the item you wish to purchase. Contact us for special lengths

|

|

PRICING FOR TRACKS AND BRACKETS

|

| Model No. |

Description |

Weight/lbs. (ea.) |

Price per 10' length |

|

|

Track (10'-0" Lengths)

|

50

|

$221.55

|

|

|

Track 11 Ga. (10'-0" Lengths)

|

35

|

$181.65

|

|

|

Twisted Track (90º Clockwise)

|

50

|

$381.15

|

|

|

Twisted Track (90º Counter Clockwise)

|

50

|

$381.15

|

|

|

Support Bracket

|

2

|

$42.00

|

|

|

Joint Bracket

|

3

|

$136.50

|

|

|

Track Welding Jig

|

1.5

|

$224.70

|

|

|

H.D. track, 6 Ga., 10' Long

|

55

|

$332.85

|

|

|

|

CONVEYOR CHAIN

|

|

|

|

|

|

2035.01974 CHAIN

|

|

|

Zig-Zag chain is made with heavy steel stampings with a

hardened inner race. Precision alloy balls make Zig-Zag

chain rugged and durable for prolonged dependable life

and operation. |

|

|

|

|

|

|

|

FEATURES |

|

|

|

|

|

6" Pitch Chain |

|

|

|

|

Zig-Zag chain has a pitch of 6" and is the shortest in the

industry. This allows up to 33 percent more productivity.

The pitch of our chain allows you to space load pendants

closer with less wheel loading, allowing for more product

throughput. This shorter pitch also allows for tighter radius

horizontal curves. We can provide standard stock 18"

radius horizontal curves. |

|

|

|

Load Pin |

|

|

|

Zig- Zag chain is manufactured with a pendant load pin.

Unlike the industry, our pendants are mounted to a load

pin and not the wheel axle. This eliminates unnecessary

wear and torsional loads to critical parts of the chain,

thereby increasing your productivity and decreasing your

downtime. |

|

|

|

|

|

|

|

Installation and Maintenance |

|

|

|

|

|

By design, Zig-Zag chain is made for ease of installation

and maintenance. Our chain may be disassembled at any

point by simply removing a cotter pin. Zig-Zag chain is

available from stock in 10' boxes or in bulk 300' barrels. |

Click the button of the item you wish to purchase. Contact us for special lengths

|

|

PRICING FOR STANDARD CONVEYOR CHAIN

|

| Model No. |

Description |

Weight/lbs. (ea.) |

Price |

|

|

Conveyor chain , 10' long, caged bearings

|

33

|

$502.95

|

|

|

Conveyor chain, 300' length (6 pieces @50' each), CB

|

990

|

$15,059.10

|

|

|

Chain Installation Kit (Links, Link Pin's Cotters)

|

1

|

$157.50

|

|

|

Chain & Bearing Cleaner Assembly

|

20

|

$3,333.75

|

|

|

Track Cleaner Brush Assembly (attaches to chain)

|

1

|

$834.75

|

|

|

|

|

STANDARD CURVES

|

|

|

|

|

|

|

|

|

|

|

|

|

| VERTICAL CURVES |

|

|

|

|

The illustration shows the action of the wheels and the manner in which they

bear against the inside of the track when going around vertical curves. The

wheels, you will note, contact the top of the track on bottom curves and the

bottom of the track on top curves. The chain, in this way, is guided around

short radius vertical curves. |

|

|

|

|

|

|

|

|

|

| HORIZONTAL CURVES |

|

|

|

The illustration shows how the chain passes around horizontal curves without

the use of special guides, sprockets, or wheel turns. |

|

Please note from the cutaway section how the lateral wheels bear on the side

of the track when the chain is drawn around curves. A series of wheels

constantly share the load imposed upon the track, thereby reducing friction

and insuring smooth conveyor operation. |

|

Curves with these radius are standard:

1'-6",2'-0", 2'-3", 3'-0", 3'-3", 4'-0" and 4'-3". |

|

|

|

|

|

Top Vertical Curve

|

|

|

|

|

|

|

|

NOTE: All curves up to 3'-0" are available hardened for increased life and

made of heavy-duty 3/16" material, heaviest in the industry. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bottom Vertical Curve

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Looking through side of track. Track cut-away of

chain passing through reverse vertical curve. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Horizontal Curve

|

|

|

|

|

|

|

|

|

|

|

Looking through top of track. Track cut-away to

give bird's eye view of chain in track, illustrating

operation in horizontal curve. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2035.02679

|

|

|

|

|

|

|

|

|

|

|

Click the button of the item you wish to purchase. Contact us for special lengths

|

|

|

|

|

PRICING FOR STANDARD HORIZONTAL CURVES

|

| Model Number |

Description |

Weight/lbs. (ea.) |

Price |

|

|

Curve 1'-6" R x 90º (hardened)

|

15

|

$496.65

|

|

|

Curve 1'-6" R x 180º (hardened)

|

24

|

$819.00

|

|

|

Curve 2'-0" R x 30º

|

6

|

$257.25

|

|

|

Curve 2'-0" R x 45º

|

8

|

$312.90

|

|

|

Curve 2'-0" R x 90º (hardened)

|

15

|

$429.45

|

|

|

Curve 2'-0" R x 180º (hardened)

|

30

|

$868.35

|

|

|

Curve 2'-3" R x 90º (hardened)

|

18

|

$431.55

|

|

|

Curve 3'-0" R x 90º

|

24

|

$469.35

|

|

|

Curve 3'-3" R x 90º

|

26

|

$495.60

|

|

|

Curve 4'-0" R x 90º

|

32

|

$499.80

|

|

|

Curve 4'-3" R x 90º

|

34

|

$502.95

|

|

|

PRICING FOR SPECIAL HORIZONTAL CURVES

|

|

Up to 5'-9" R x 90° or less

|

|

$797.90 |

|

6'-0" to 11'-9" R x 45° or less

|

|

|

|

$822.89 |

|

|

|

|

|

|

|

|

|

PRICING FOR STANDARD VERTICAL CURVES

|

| Model Number |

Description |

Weight/lbs. (ea.) |

Price |

|

|

Top Vertical Curve 2'-0" x 30º

|

6

|

$247.80

|

|

|

Bottom Vertical Curve 2'-0" x 30º

|

6

|

$247.80

|

|

|

Top Vertical Curve 2'-0" x 45º

|

8

|

$302.40

|

|

|

Bottom Vertical Curve 2'-0" x 45º

|

8

|

$302.40

|

|

|

Top Vertical Curve 2'-0" R x 90º

|

25

|

$473.55

|

|

|

Bottom Vertical Curve 2'-0" R x 90º

|

25

|

$473.55

|

|

|

Top Vertical Curve 4'-0" R x 90º

|

53

|

$1,855.35

|

|

|

Bottom Vertical Curve 4'-0" R x 90º

|

53

|

$1,855.35

|

|

| NOTE: All horizontal curves are cut off at the tangents and do not include any straight track. |

|

|

FIELD FABRICATED CURVES

|

|

|

|

|

| VERTICAL CURVE DATA |

|

|

|

|

|

Note: The Vertical Curve dimensions in the chart

below are based on using 2'-0" radius curves. |

|

|

|

|

| 45°, 2'-0" radius vertical curve shown. |

|

|

|

|

|

| A |

30° |

45° |

60° |

| B |

C |

D |

B |

C |

D |

B |

C |

D |

| 6 7/16" |

0'-0" |

2'-0" |

2'-1 1/8" |

- |

- |

- |

- |

- |

- |

| 9" |

0'-5 1/8" |

2'-4 7/16" |

2'-6 1/4" |

- |

- |

- |

- |

- |

- |

| 12" |

0'-11 1/8" |

2'-9 5/8" |

3'-1/4" |

- |

- |

- |

- |

- |

- |

| 1'-2" |

1'-3 1/8" |

3'-1 1/8" |

3'-4 1/4" |

1/16" |

2'-9 15/16" |

3'-1 11/16" |

- |

- |

- |

| 1'-6" |

1'-11 1/8" |

3'-8 1/16" |

4'-1/4" |

5 9/16" |

3'-1 7/8" |

3'-7 1/4" |

- |

- |

- |

| 1'-9" |

2'-5 1/8" |

4'-1 1/4" |

4'-6 1/4" |

9 13/16" |

3'-4 7/8" |

3'-11 1/2" |

- |

- |

- |

| 2'-0" |

2'-11 1/8" |

4'-6 7/16" |

5'-1/4" |

1'-2 1/6" |

3'-7 7/8" |

4'-3 3/4" |

0'-1/16" |

3'-5 9/16" |

4'-2 1/4" |

| 2'-3" |

3'-5 1/8" |

4'-11 5/8" |

5'-6 1/4" |

1'-6 5/16" |

3'-10 7/8" |

4'-8" |

0'-3 7/16" |

3'-7 5/16" |

4'-5 3/4" |

| 2'-6" |

3'-11 1/8" |

5'-13/16" |

6'-1/4" |

1'-10 9/16" |

4'-1 7/8" |

5'-1/4" |

0'-6 15/16" |

3'-9 1/16" |

4'-9 3/16" |

| 2'-9" |

4'-5 1/8" |

5'-10" |

6'-6 1/4" |

2'-2 13/16" |

4'-4 7/8" |

5'-10 1/8" |

0'-10 3/8" |

3'-10 3/4" |

5'-11/16" |

| 3'-0" |

4'-11 1/8" |

6'-3 3/16" |

7'-1/4" |

2'-7 1/16" |

4'-7 7/8" |

5'-8 3/4" |

1'-1 7/8" |

4'-1/2" |

5'-4 1/8" |

| 3'-6" |

5'-11 1/8" |

7'-1 5/8" |

8'-1/4" |

3'-3 1/2" |

5'-1 7/8" |

6'-5 3/16" |

1'-8 13/16" |

4'-3 15/16" |

5'-11 11/16" |

| 4'-0" |

6'-11 1/8" |

8'-0" |

9'-1/4" |

4'-1/16" |

5'-7 7/8" |

7'-1 11/16" |

2'-3 11/16" |

4'-7 7/16" |

6'-6" |

| 4'-6" |

7'-11 1/8" |

8'-10 3/8" |

10'-1/4" |

4'-8 1/2" |

6'-1 7/8" |

7'-10 13/16" |

2'-5/8" |

4'-10 7/8" |

7'-15/16" |

| 5'-0" |

8'-11 1/8" |

9'-8 13/16" |

11'-1/4" |

5'-5 1/16" |

6'-7 7/8" |

8'-6 11/16" |

3'-5 9/16" |

5'-2 3/8" |

7'-7 13/16" |

| 5'-6" |

9'-11 1/8" |

10'-7 13/16" |

12'-1/4" |

6'-1 7/16" |

7'-1 7/8" |

9'-3 1/8" |

4'-1/2" |

5'-5 13/16" |

8'-2 3/4" |

| 6'-0" |

10'-11 1/8" |

11'-5 9/16" |

13'-1/4" |

6'-9 15/16" |

7'-7 7/8" |

9'-11 5/8" |

4'-7 7/16" |

5'-9 5/16" |

8'-9 11/16" |

| 6'-6" |

11'-11 1/8" |

12'-3 15/16" |

14'-1/4" |

7'-6 7/16" |

8'-1 7/8" |

10'-8 1/8" |

5'-2 3/8" |

6'-3/4" |

9'-4 5/8" |

| 7'-0" |

12'-11 1/8" |

13'-2 3/8" |

15'-1/4" |

8'-2 15/16" |

8'-7 7/8" |

11'-4 5/8" |

5'-9 5/16" |

6'-4 3/16" |

9'-11 9/16" |

| 7'-6" |

13'-11 1/8" |

14'-3/4" |

16'-1/4" |

8'-11 3/4" |

9'-1 7/8" |

12'-1 1/8" |

6'-4 3/16" |

6'-7 11/16" |

10'-6 1/2" |

| 8'-0" |

14'-11 1/8" |

14'-11 1/8" |

17'-1/4" |

9'-7 7/8" |

9'-7 7/8" |

12'-9 9/16" |

6'-11 1/8" |

6'-11 1/8" |

11'-1 3/8" |

| 8'-6" |

15'-11 1/8" |

15'-9 1/2" |

18'-1/4" |

10'-4 3/4" |

10'-1 7/8" |

13'-6 1/16" |

7'-6 1/16" |

7'-2 5/8" |

11'-8 5/16" |

| 9'-0" |

16'-11 1/8" |

16'-7 15/16" |

19'-1/4" |

11'-7/8" |

10'-7 7/8" |

14'-2 9/16" |

8'-1" |

7'-6 1/16" |

12'-3 1/4" |

| 9'-6" |

17'-11 1/8" |

17'-6 5/16" |

20'-1/4" |

11'-9 5/16" |

11'-1 7/8" |

14'-1 1/16" |

8'-7 15/16" |

7'-9 1/2" |

12'-10 3/16" |

| 10'-0" |

18'-11 1/8" |

18'-4 11/16" |

21'-1/4" |

12'-5 13/16" |

11'-7 7/8" |

15'-7 1/2" |

9'-2 7/8" |

8'-1" |

13'-5 1/8" |

| 10'-6" |

19'-11 1/8" |

19'-3 1/8" |

22'-1/4" |

13'-2 5/16" |

12'-1 7/8" |

16'-4" |

9'-9 3/4" |

8'-4 7/16" |

14'-1/16" |

| 11'-0" |

20'-11 1/8" |

20'-1 1/2" |

23'-1/4" |

13'-10 13/16" |

12'-7 7/8" |

17'-1/2" |

10'-4 11/16" |

8'-7 15/16" |

14'-7" |

| 11'-6" |

21'-11 1/8" |

20'-11 7/8" |

24'-1/4" |

14'-7 1/4" |

13'-1 7/8" |

17'-9" |

10'-11 5/8" |

8'-11 3/8" |

15'-1 7/8" |

| 12'-0" |

22'-11 1/8" |

21'-10 1/4" |

25'-1/4" |

15'-3 3/4" |

13'-7 7/8" |

18'-5 7/16" |

11'-6 9/16" |

9'-2 7/8" |

15'-8 13/16" |

| 12'-6" |

23'-11 1/8" |

22'-8 11/16" |

26'-1/4" |

16'-1/4" |

14'-1 7/8" |

19'-1 15/16" |

12'-1 3/8" |

9'-6 5/16" |

16'-3 3/4" |

|

|

|

TAKE-UP ASSEMBLIES

|

|

| 2035.01687 FRAMED TAKE-UP |

|

|

|

|

|

|

|

Note: Complete unit consists of one frame and one

set of hardware for screw, spring or air take-up. |

|

Ready to be hoisted and hung, this frame provides a rigid base and

helps make alignment positive. The frame is permanently mounted;

only the actuator and conveyor move. Tensioning is accomplished

with your choice of screw, spring, or air cylinder packages listed

below. Available for 2'-0" R curves (4' maximum track spread). |

|

|

|

|

|

|

|

|

|

|

|

|

Some type of tensioning is necessary on all Zig-Zag conveyor

systems to take up slack chain created by wear or temperature

changes. We make screw take-up fittings for field assembly. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Framed Take-Up Assembly

|

|

|

Air Package

|

|

Screw Package

|

|

|

|

|

|

|

|

|

TAKE-UP FITTINGS AND EXPANSION SLEEVE

|

|

|

|

2035.00583 SCREW

TAKE-UP FITTINGS

(1'-6" Travel) |

|

|

|

|

|

|

|

|

|

|

2035.02497 AIR

TAKE-UP FITTINGS

(1'-0" Travel) |

|

|

NOTE: Curves are not included in

assembly. |

|

|

|

|

|

|

|

|

|

|

|

2035.00304 Safety Anti-Rollback Assembly |

|

Safety Anti-Rollback Assembly for chain

is used as a safety device in the event of

a possible chain separation due to over-

loading conditions or jams. The unit is

designed for installation on the incline

portion of a vertical curve, and will act-

ivate the stop-finger to drop and wedge

in the chain if a chain separates, breaks,

or fails. Finished with powder coating. |

|

2035.00583

|

|

|

|

|

|

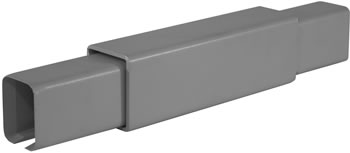

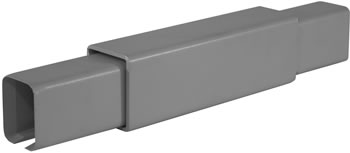

2035.0114 EXPANSION SLEEVE

|

|

|

2035.02671 Anti-Runaway Bolted Assembly

|

|

|

|

|

|

|

|

|

|

|

|

|

Weight: 20 lbs |

|

|

|

The 2035.02671 Anti-Runaway Bolted Assembly is used as a

safety device in the event of a chain break or an improper

engagement of the pusher dog and carrier assembly. Designed

for installation on the decline portion of a vertical curve.

Operation: A sudden increase in chain or carrier speed will

cause the cam to bounce upward and release the trigger

mechanism; plunger will drop into the path halting the next

chain wheel. Finished in powder coating. |

|

|

|

|

Expansion sleeves are used mainly in bake ovens and are

located in each track in the area of the oven expansion joint.

This allows both oven and conveyor to expand and contract

in unison. Many ovens, depending on length and temperature,

do not have expansion joints. In such cases, it is often

advisable to use an expansion sleeve at the exit and entrance

tracks to prevent snaking or waviness in the track both inside

and outside the oven.

|

|

|

|

|

|

|

|

2035.02497 Air Take-up Fittings, 12 inch travel |

|

|

|

|

|

|

|

The 2035.02497 Air Take-Up Package

has a 12" travel and is finished with

powder coating. Package includes

tubing, fittings, regulator with gage

and shut-off valve.Curves must be

purchased separately and must not

exceed a 4 foot radius. |

|

|

|

|

Relative to installation, the movable track in the sleeve

should be moved out 2" from the compressed length which

would then be an overall of 1'-6" instead of 1'-4" as shown.

This allows for both contraction and expansion in the track. |

|

|

|

|

|

|

|

|

2035.01990 Screw Take-up Fittings, 48 inch Travel

|

|

|

|

|

|

|

|

|

|

|

|

Screw Take-Up Fittings have a 48' travel and are finished with

powder coating.Curves must be purchased separately and must

not exceed a 4 foot radius. |

|

|

|

|

|

|

|

|

|

|

Click the button of the item you wish to purchase. Contact us for special lengths

|

|

PRICING FOR STANDARD TAKE-UP FITTINGS

|

| Model Number |

Description |

Weight/lbs. (ea.) |

Price |

|

|

Short Screw Take-Up Sleeve Assembly (need 2 per take-up)

|

10

|

$705.60

|

|

|

Screw Take-Up Fittings (18" Travel)

|

80

|

$2,420.25

|

|

|

Air Take-up Fittings (12" Travel)

|

85

|

$5,100.90

|

|

|

Framed Take-Up Basic Assembly (12" Travel)

|

185

|

$4,144.35

|

|

|

Screw Take-Up Package (12" Travel)

|

10

|

$344.40

|

|

|

Spring Take-up Package (12" Travel)

|

19

|

$529.20

|

|

|

Air Take-up Package (12" Travel)

|

55

|

$2,053.80

|

|

|

Limit Switch Package (1 Limit Switch w/Bracket)

|

10

|

$1,628.55

|

|

|

Expansion Sleeve

|

8

|

$430.50

|

|

|

Safety Stop (Anti Back-Up)

|

3

|

$512.40

|

|

|

Anti-Runaway Assembly

|

20

|

$1,363.95

|

|

|

Screw-Up Fittings (48' Travel)

|

120

|

$3,147.90

|

|

|

SKELETON DRIVE

|

|

|

|

|

|

The 2035.01373 skeleton drive unit incorporates the use

of a caterpillar drive chain connection to the head shaft

and idler shaft assembly. The skeleton drive is not equip-

ped with a motor, reducer, friction clutch, driven sprocket,

or roller chain. |

|

|

2035.01373 (shown with Chain Guards)

|

|

|

|

|

|

|

|

The skeleton drive unit is used in Zig-Zag, Twin-Trak and

OveR-Way applications. Most commonly, the unit is used

where the customer needs to replace their existing drive,

but wants to use the existing motor, reducer, and sprockets.

The skeleton is also used where the customer wants to

supply his own motor, reducer, and sprockets. The unit can

be used with an extended head shaft and jackshaft to join

two or more conveyors together for timing purposes. |

|

|

2035.01373 (shown without Chain Guards)

|

|

|

|

|

|

|

|

| The capacity of the unit is 750 lbs. Chain Pull. |

|

|

|

|

|

|

|

|

|

|

Click the button of the item you wish to purchase. Contact us for special lengths

|

PRICING FOR DRIVE UNITS

|

Model

Number |

Description |

Weight/lbs.

(ea.) |

Price |

|

|

Drive Unit (Variable Speed 3 to 16 F.P.M. when used with A.C. Inverter Control listed below)230/460/3/60 T.E.F.C. 3/4 H.P. Motor NOTE: at 60 cycle line current constant speed 16 F.P.M.

|

305

|

$13,680.45

|

|

|

Drive Unit (Variable Speed 9 to 45 F.P.M. when used with A.C. Inverter Control listed below)230/460/3/60 T.E.F.C. 1-1/2 H.P. Motor NOTE: at 60 cycle line current constant speed 45 F.P.M.

|

315

|

$13,716.15

|

|

|

Skeleton Drive Unit

|

215

|

$8,108.10

|

|

|

Encoder Adapter

|

-

|

$1,032.15

|

|

|

Skeleton Drive Unit with Ext. Shaft

|

-

|

$8,295.00

|

|

|

Lift up Drive Unit (16 F.P.M.) 230/460/3/60 T.E.F.C. 3/4 H.P. Motor

|

325

|

$16,993.20

|

|

|

Lift up Drive Unit (45 F.P.M.) 230/460/3/60 T.E.F.C. 1 1/2 H.P. Motor

|

335

|

$17,770.20

|

|

|

Drive Unit with Ext. Shaft (16 F.P.M.)

|

-

|

$14,389.20

|

|

|

Drive Unit with ext. Shaft (45 F.P.M.)

|

-

|

$14,890.05

|

| Special |

Drive Unit (Non-Standard Speed Max. 90 F.P.M.) Variable 5:1 speed range when used

with the proper AC Inverter Control listed below |

- |

Consult Us |

|

NOTE: All motors are 230/460 volts, 3 phase, 60 hertz, but inverters require 230 volts, 3 phase input power. Check with us for other current

characteristics. |

|

|

LUBRICATION AND INSPECTION SECTION

|

|

The proper lubrication of the conveyor chain is of paramount

importance not only to the successful operation of a conveyor

system, but to the life of the product as well. Proper lubricant

should be recommended by a qualified lubricating engineer who

has made a study of the processing machinery and atmospheric

conditions to which the system will be subjected. Special safe-

guards must be taken to protect the chain when it moves through

high temperatures, extremely low temperatures, acid conditions

such as bonderizing, alkaline washers, or other chemicals which

could reduce the life of the bearings and other parts. We caution

against the use of graphite based lubricants which tend to build

up excessive deposits of foreign matter unless the chain is

thoroughly cleaned at regular intervals. We urge the use of our

sanitary hook in acid or paint spray conditions. |

|

|

|

|

|

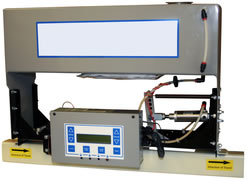

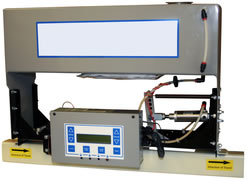

2035.02724 Automatic Timer

Controlled Lubricator

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| No. 2035.02724 Automatic Timer Controlled Lubricator |

|

|

|

|

|

This automatic timer controlled lubricator is designed to precisely

lubricate the critical bearing points of the conveyor chain. It has

five nozzles, located to dispense lubricant on the vertical and lateral

wheel bearings, vertical link pin and roller. Each nozzle has its own

adjustable valve to control the amount of lubricant that is dispensed.

It is equipped with a 168 hour adjustable timer which can be set for

as little as 20 minutes out of 168 hours of conveyor operation. |

|

|

|

|

|

|

|

|

|

|

|

|

| No. 2035.00669 Electro-Brush Oiler |

|

|

|

|

|

The illustration shows the brush type oiling device. The brush makes

contact with the chain, distributing the lubricant to the various parts.

A 115 volt solenoid shut-off valve is provided at the bottom of the

tank reservoir. |

|

|

|

|

|

|

Electro-Brush Oiler

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| No. 2035.00664 Brush Oiler |

|

|

|

|

|

The brush oiler applies lubrication to the chain by gravity feed. The

brush makes contact with the chain, distributing the lubricant to the

various parts. A toggle shut off at the top of the reservoir is provided.

NOTE: We do not recommend this oiler in finishing systems. |

|

|

|

|

|

|

|

|

|

|

|

|

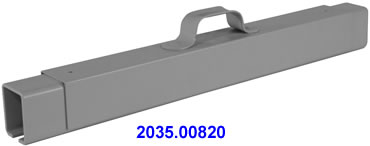

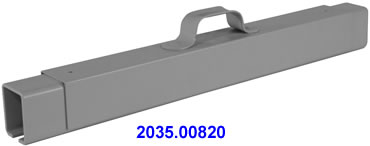

| No. 2035.00820 Inspection Track Section |

|

|

|

|

|

|

The inspection track section, formed out of this 3/16" track,

facilitates inspection and maintenance at points other than

the drive unit. It may be placed in any run of straight track.

This section is made with the top and sides open down to

the center of the chain. This allows for full inspection of the

chain for proper lubrication, chain tension, and general

condition of the conveyor chain. The opening is covered

by a removable housing and is equipped with a handle. The

inspection section also permits easy installation and removal

of chain. The most desirable location is at the lowest point

between the output of the drive unit and the take-up unit.

The inspection section is furnished in a standard finish to

match the rest of the system. |

|

|

|

|

|

|

|

|

Brush Oiler for Chain,

Manual Gravity Flow

|

|

|

|

|

|

|

|

|

|

|

|

|

The inspection section is used in all Zig-Zag, Twin-Trak,

and OveR-Way systems. In certain applications, such as

a large system, it may be desirable to use several inspection

sections. |

|

|

Inspection Section

|

|

|

|

|

|

|

|

|

|

|

|

|

2035.02893 Lubricator for Chain

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2035.02771 LUBRICANT, 5-GAL

|

|

|

|

|

|

|

|

2035.03050 Lubricant, 5 Gallon Container, High Temperature |

|

|

|

|

|

|

|

|

|

|

|

|

|

The 2035.02771 Lubricant container size:

5 gallon. Recommended for use on conveyor

systems that are exposed to temperatures up

to 450 degrees F. |

The 2035.02893 Lubricator for Chain is

designed to precisely lubricate the critical

bearing points of the conveyor chain. The

lubricator has five ejector tubes to dispense

the lubricant into the vertical and horizontal

wheel bearings along with the vertical link

pin and roller.The unit has a micro-processor

to accurately control the amount of lubricant

that is dispensed. Pre-mounted onto a 2'-6"

long track section, has a 5.5 gallon reservior

with low level alarm, 120V at 1 Amp, no air

lines required. Lubricants sold separately. |

|

|

|

|

|

|

|

The 2035.03050 Lubricant, container size:

5 gallon. This lubricant is designed for use

with washer lines, liquid and powder paint.

Recommended for use on Zig-Zag system

that are exposed to temperatures up to 500

degrees F. |

|

|

|

|

|

|

|

Click the button of the item you wish to purchase. Contact us for special lengths

|

|

PRICING FOR LUBRICATION AND INSPECTION SECTION

|

| Model No. |

Description |

Weight/lbs. (ea.) |

Price |

|

|

Brush Type Oiler

|

13

|

$1,127.70

|

|

|

Electro Brush Oiler, 120 Volt

|

14

|

$1,460.55

|

|

|

Brush Only (for repair, all brush oilers)

|

0.2

|

$80.85

|

|

|

Automatic Chain Pin and Wheel Lubricator w/115 Volt Timer for Auto On-Off Control

|

55

|

$8,814.75

|

|

|

Inspection Section

|

16.5

|

$385.35

|

|

|

Lubricant - 5 gal - 180° Max LL

|

37

|

$703.50

|

|

|

Automatic Chain Lubricator-Self Contained Mighty Lube

|

54

|

$8,974.35

|

|

|

Lubricant - 5 gal - 180° Max ML

|

37

|

$689.85

|

|

|

Lubricant - 5 gal - 450° Max SS-3

|

40

|

$705.60

|

|

|

2035 STANDARD LOAD PENDANTS

|

|

|

|

|

|

|

We have developed a series of standard load

carrying devices designed to cover the

essential requirements for connecting the load

to the conveyor chain. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Since the ultimate device required to carry the

load on the conveyor must be specially de-

signed to fit the article which is being handled,

it is almost impossible to illustrate a load pen-

dant for every problem. It is also desirable in

many cases to experiment with various types

of load carriers before finding the one most

satisfactory for the job. |

|

|

|

|

2035.00201 Long Pusher Lug

Assembly, Hold Back Dog

|

|

|

|

|

|

|

|

The 2035.00201 Long Pusher Lug /

Hold Back Dog was primarily used

to limit the carriers momentum on

gravity feed and accumulation lines

for Twin-Track Power & Free con-

veyor systems. The function is to

provide the ability to accumulated a

series of carriers one behind the

other. Attach the Long Pusher Lug

/Hold Back Dog to the load pin on

the conveyor chain by rotating the

center plate, align the holes, insert &

tighten the fastener (not included).

Zinc plated finish; may be spaced on

multiples of 6". |

|

|

|

|

Almost any type of load suspension fitting

can be attached to the 2035.00319 clevis

pendant.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2035.00319 Standard Clevis Load

Pendants, Capacity 75 lbs.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pusher Dog, Malleable Iron

|

|

Delatching Pusher Dog Assembly

|

|

2035.02694 Rigid Clevis Pendant

|

The 2035.01155 Pusher Dog is composed of

a connecting bar with moveable flipper lugs

and two attachment pendants. The connect-

ing bar is attached to the conveyor chain

with the pendants, nuts, and cotter pins.

Furnished in a zinc plate finish. |

|

The 2035.01188 Delatching Pusher Dog

Assembly is composed of two pendants,

two side plates, two side plate spacers,

one hold- back flipper and one propelling

flipper. Parts are assembled in the field and

attached to the conveyor chain load pins

with hex bolts and lock nuts. Pendants are

zinc plate finish; flippers & side plates are

black oxide. |

The 2035.02694 Rigid Clevis Pendant

has a 75 lb load capacity and there is

an offset in the pendant sides, to allow

for a 1/2" gap. The rigid style of pen-

dant is used where swinging loads is

not permitted. The rigid pendant always

remains per- pendicular to the track.It

uses a scissor- like action to attach

directly to the load pin on the vertical

link of the conveyor chain. In the

closed position the pendant grips the

load pin reducing premature chain wear.

Zinc plated finish; may be spaced on

multiples of 6". |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

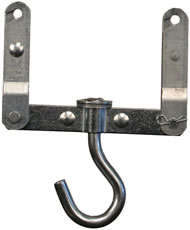

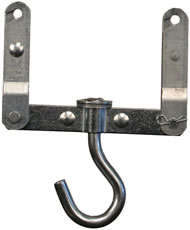

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Part 2035.00318

|

|

Part 2035.00316

|

|

Part 2035.00317

|

|

Straight Side Pendant

|

|

Rigid Clevis Pendant

|

|

Rigid Straight Side Pendant

|

The Straight Side Pendant is similar to the

Standard Clevis Pendant except the pendant

sides are straight. It uses a scissor like

action to attach directly to the load pin on

the vertical link of the conveyor chain. The

pendant may be spaced on multiples of 6".

The pendant is furnished in a zinc plated

finish. This type of pendant is used where it

is permitted to have swinging loads. The

pendant is allowed to pivot, as the conveyor

makes elevation changes. |

|

The Rigid Clevis Pendant is designed to

be used where a swinging load may be

objectionable. This pendant is similar to

the Rigid Straight Side Pendant except

there is an offset in the pendant sides

to allow for a 1/4" gap. The pendant may

be spaced on multiples of 6". The pendant

is furnished in a zinc plated finish. This

pendant always remains perpendicular to

the track. The pendant can be attached

to a load bar or directly to a product rack. |

|

The Rigid Straight Side Pendant is similar

to the Rigid Clevis Pendant except the sides

are straight. It may be spaced on multiples

of 6". It attaches directly to the load pin

on the vertical link of the conveyor chain

and is furnished in a zinc-plated finish.

This pendant may be used where a swin-

ging load may be objectionable or not

permitted. The pendant always remains

perpendicular to the track. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

No. 2035.00264 Rigid

"V" Pendant

|

|

|

|

|

|

|

|

No. 2035.02706 Suspension

Indexing Load Hook

|

|

|

|

|

|

No. 2035.02775 Swivel Fixture

|

|

|

Capacity 75 lbs. Max.*

|

|

Capacity 75 lbs. Max.

|

|

|

|

Capacity 75 lbs.

|

|

|

|

This fixture permits continuous rotation

of a product through a finishing operation

by permitting the ball-bearing roller to turn

against a continuous flat bearing strip,

through the turning area. |

|

Standard offset of 8" as shown may be

increased on special order to 11" maximum

for vertical travel or any desired offset for

horizontal travel, and decreased to a min-

imum of 3 1/4". |

|

|

|

|

The load hook illustrated above is used to

carry loads that must be indexed from time

to time by the operator at 90°. Bottom of

track to throat of hook 3/8". |

|

|

|

|

|

|

|

|

|

|

|

|

|

*Where unit loads are less than 8 lbs

minimum preloading is recommended to

insure smooth rotation. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

No. 2035.00257 DOUBLE

SUSPENSION LOAD HOOK

|

|

No. 2035.02772 DOUBLE SUSPENSION

LOAD BAR ASSEMBLY

|

|

No. 2035.02702 DOUBLE SUSPENSION LOAD HOOK ASSEMBLY

|

|

Capacity 150 lbs.

|

|

Capacity 150 lbs. per assembly

|

|

Capacity 150 lbs. per assembly

|

The load is suspended from two vertical

load units increasing the capacity of the

load carrier. Standard clevis pendants are

attached to the conveyor chain on 6"

centers. The load hook revolves freely. |

|

By suspending the load from two points

on the chain, the load carrying capacity is

increased. This pendant can be attached

to the conveyor chain on a minimum of

12" centers. The basic load bar assembly

provides a means of attaching a product

hook or clevis directly to the center hole. |

|

By suspending the load from two points

on the chain, the load carrying capacity is

increased. This pendant can be attached to

the conveyor chain on a minimum of 12"

centers. The Load Hook assembly is used

for finishing applications where the load

must be manually indexed in 90°

increments. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2035.00198 Swivel

Fixture Pendant

|

97100.73 Spray Paint

12 Oz. Can, Pebble Tan |

|

No. 2035.02699 DOUBLE SUSPENSION

ROTATING STAR INDEXING PENDANT

|

|

|

The 2035.00198 Swivel Fixture Pendant

allows continuous rotation of a product

through a finishing operation by permitting

the ball-bearing roller to turn against a con-

tinuous flat bearing strip through the turning

area. 75 lb load capacity; 4-1/2" drop; zinc

plated finish and may be spaced on multiples

of 6". |

Size: 12 oz aerosol spray

can. Color: Pebble Tan.

NOTE: Paint creates a

textured finish. |

|

Capacity 150 lbs. for manual indexing

|

|

Distance from bottom of track to throat of

hook is 8 7/8". This pendant can be used to

manually index or automatically index the

part. This pendant can be used with a

Rotating Cam or Continuous Rotating Cam,

permitting automatic rotation and indexing

in increments of 90°. The pendants and load

bar have a zinc plated finish while the hook

assembly is finished in Gloss-Tek powder

coat. This pendant is most commonly used

for finishing applications where it is neces-

sary to rotate the part. This pendant assem-

bly can be spaced on 6" increments with a

minimum of 12" centers. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2035.02693 Indexing Load Hook Assembly,

with Cross Bar, 75 Lb. Capacity

|

|

No. 2035.00430 MULTIPLE SUSPENSION LOAD HOOK

|

|

Capacity 300 lbs.

|

The 2035.02693 Indexing Load Hook Assembly with Cross Bar

has a 75 lbs. capacity and is a two piece design with the rigid

pendant and cast hook assembly. The pendant may be spaced

on multiples of 6". The pendant has a zinc plated finish and the

hook has a raw cast finish. |

|

By suspending the load from four points on the chain, the

load carrying capacity is increased again. Standard clevis

pendants are attached at four points to each vertical link

pendant, and the load bar is free to swivel so that there will

be no binding action when going around curves. Bottom of

track to throat of hook is 9 1/16" |

|

|

|

|

Click the button of the item you wish to purchase. Contact us for special lengths

|

|

PRICING FOR 2035 STD LOAD PENDANTS

|

| Model No. |

Description |

Weight/lbs. (ea.) |

Price |

|

|

Holdback Dog

|

0.5

|

$53.11

|

|

|

Double Suspension Load Hook

|

2

|

$96.61

|

|

|

"V" Pendant-8" Drop (standard)

|

1.8

|

$85.24

|

|

|

Rigid Clevis Pendant

|

0.5

|

$14.95

|

|

|

Rigid Straight Side Pendant

|

0.5

|

$14.95

|

|

|

Straight Side Pendant

|

0.5

|

$16.06

|

|

|

Standard Clevis Pendant

|

0.5

|

$16.06

|

|

|

Multiple Suspension Load Hook

|

9.5

|

$386.45

|

|

|

Holdback Dog Spring

|

0.1

|

$14.06

|

|

|

Malleable Iron Pusher Dog

|

3

|

$213.31

|

|

|

Rivet for Holdback Dog

|

0.5

|

$2.46

|

|

|

Delatching Pusher Dog

|

4

|

$254.36

|

|

|

Single Suspension Indexing Load Hook Assembly

|

0.5

|

$124.06

|

|

|

Pendant Assembly for Cast Hook

|

0.5

|

$38.38

|

|

|

Spin Hook Pendant

|

0.5

|

$28.78

|

|

|

Double Suspension Load Bar Assembly

|

2

|

$65.37

|

|

|

Double Suspension Indexing Hook Assembly

|

3

|

$270.43

|

|

|

Double Suspension Rotating Hook Assembly

|

1.5

|

$223.12

|

|

|

Single Suspension Load Hook Assembly

|

0.5

|

$107.10

|

|

|

Swivel Fixture Assembly

|

5

|

$35.92

|

|

|

Touch-Up Paint (Pebble Tan) 12 oz. Spray Can

|

1

|

$17.85

|

|

|

|

INVERTED CONVEYOR COMPONENTS

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2035.01220 Inverted

Rigid Pendant Assembly |

2035.02091 Inverted

Standard Pendant

|

2035.02817 Inverted Light

Duty Load Hook

|

2035.02818 Inverted

Heavy Duty Load Hook

|

The 2035.01220 Inverted Rigid

Pendant Assembly is a three-

piece investment cast design

which is rated for a 75 lb load

capicity. The two pendant halves

mate over the chain's axle and

load pin, and are secured with a

cast shoulder cap. Pendant is

designed to be used with con-

veyor chain and is normally used

in pairs, connected by a shoe

which carries the product hanger. |

The 2035.02091 Inverted Stand-

ard Pendant is a one-piece

investment casting which is rated

for a 75 lb load capicity for use

with standard conveyor chain

within Inverted Zig-Zag track.

Pivoting of the pendant provides

up to a maximum of 30 degrees in

an elevation change. |

The 2035.02817 Inverted Light

Duty Load Hook has a 4-1/2"

offset and a 12-5/16? drop that

can be used as a replacement

part on any Inverted Zig-Zag

Conveyor. Load capacity: 25 lbs. |

The 2035.02818 Inverted Heavy

Duty Load Hook has a 4-9/16"

offset and a 12-7/16? drop,

which can be used as a

replacement part on any

Inverted Zig-Zag Conveyor

system. Load capacity: 75

pounds. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2035.02334 Inverted Inspection Section

|

|

|

The 2035.02334 Inverted Inspection

Section is made from standard 7 GA track

and facilitates inspection and maintenance

at points other than the drive unit. For

easy access the section is made with the

top and sides of the track open, down to

the center of the chain. This allows for full

inspection of the chain for proper lubrica-

tion, chain tension, and general condition

of the conveyor chain. Opening housings

can be unbolted from body. Section also

permits easy installation and removal of

chain and may be located in any straight

run of track, with most desirable location

at the lowest spot between the output of

the drive unit and the take-up. Finished

with powder coating. |

2035.02128 Inverted

Screw Take-up Package |

|

2035.02328 Inverted Air

Take-up Fittings Package

|

|

The 2035.02128 Inverted Screw Take-

Up Package removes chain slack by

manually adjusting the threaded rod

at the inverted curves. Normally used

with standard 2'-0" radius inverted

curves, or can be used where the track

spread is greater than 4'-0" (up to a

14'-0" max.). The 90° curves are not

included and must be ordered sep-

arately. The components are finished

with powder coating. |

|

The 2035.02328 Inverted Air Take-up Package

has two air cylinders that automatically move

the inverted curves to remove slack from the

system chain. Used with standard 2'-0" radius

inverted curves, or where track-spread is

greater than 4'-0" (up to a 14'-0" max.). The 90°

curves are not included and must be ordered

separately. Includes tubing, fittings, regulator

with gauge and shut-off valve and is finished

in powder coating. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 2035.02760 Inverted Lubricator for Chain |

|

2035.02815 Inverted Drive Unit, 16 FPM, 3/4 HP

|

The 2035.02760 Inverted Lubricator for Chain has a

self-contained 2 gallon reservoir, and is controlled

by a programmable relay inside the electrical panel.

Control can be set for ON (Lubricating) and OFF

(Non-Lubricating). Lubricator has six (6) nozzles,

strategically located to dispense lubricant to the

vertical and lateral wheel bearings along with the

vertical link pin and roller. The air inlet pipe size is

1/4" N.P.T. Minimum of 60 PSI is required

for the lubricator to function properly with lubri-

cants up to 30W. Power requirement: 110-130V AC

50/60 Hz, 1 amp service. |

|

The 2035.02815 Inverted Drive Unit, 16 FPM, 3/4 HP inverter duty

motor (208/230/480-3P), motor, reducer, and clutch are connected

with sprockets and roller chain to the head shaft, which drives the

caterpillar chain. Adequate protection is provided for reasonable

momentary overloads, and a friction clutch provides for protection

against excessive overload. Finished with powder coating. |

|

|

Click the button of the item you wish to purchase. Contact us for special lengths

|

|

PRICING FOR INVERTED CONVEYOR COMPONENTS

|

| Model No. |

Description |

Weight/lbs. (ea.) |

Price |

|

|

Inverted Pendant - Rigid Type

|

0.9

|

$119.60

|

|

|

Inverted Pendant - Standard Type

|

0.5

|

$31.69

|

|

|

Load Hook, Inverted - Light Duty 18" Lg.

|

1.5

|

$132.09

|

|

|

Load Hook, Inverted - Heavy Duty 18 1/2" Lg.

|

4

|

$371.28

|

|

|

Horizontal Curve 1'-6" R x 90 HD, Inverted

|

12

|

$482.84

|

|

|

Horizontal Curve 2'-0" R x 90 HD, Inverted

|

15

|

$527.47

|

|

|

Horizontal Curve 3'-0" R x 90 HD, Inverted

|

24

|

$570.31

|

|

|

Inverted Screw Take-Up Fittings

|

80

|

$2,556.12

|

|

|

Inverted Air Take-Up Fittings

|

85

|

$5,801.25

|

|

|

Inverted Inspection Section

|

16

|

$724.71

|

|

|

Inverted conveyor Chain Lubricator - PLC

|

40

|

$15,657.13

|

|

|

Inverted Drive Unit 16 FPM, 3/4 HP

|

305

|

$13,773.06

|

|

|

Inverted Drive Unit 45 FPM, 1-1/2 HP

|

315

|

$14,283.57

|

|

|

Inverted Track Bracket

|

3

|

$85.24

|

|

|

|

|

PRICING FOR CONVEYOR SYSTEM CONTROL PANELS

|

| Model No. |

Description |

Weight/lbs. (ea.) |

Price |

|

|

Basic Control Panel, NEMA #12, Single Drive NEMA #12 Enclosure Approx. 20" x 8: x 20" 2/Main Power Supply disconnect; External Mounted Start-Stop Push Button, E-Stop, A-B Component Touch Screen OI; Internally Mounted A-B Powerflex 525 Drive Control& A-B Micro 800 PLC.

|

95

|

$34,167.59

|

|

|

Control Panel, NEMA #12, Single Drive, 3/4 HP to 2 HP

|

100

|

$55,217.19

|

|

|

Control Panel, NEMA #12, Dual Drive, 3/4 HP to 2 HP

|

112

|

$61,944.86

|

|

Single and Dual Drive Control Panels - NEMA #12 Enclosure (24" x 24") with Main Power Supply Disconnet;

Externally Mounted and Wired Warning Horn, Tower Light, E-Stop Push Button, Operator Interface Terminal;

Internally Mounted Micrologix 1200 PLC, VFD, Terminals for External Devices; Control Functions include:

Speed Adjustment, Motor Jog, Lubricator enable/disable, System Status; Load Sharing (Dual Drive) is achieved

thru Parameter Adjustment of Load and Slip Compensation Settings on VFD's. |

|

|

HORIZONTAL TRACTION WHEEL TURNS

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2035.02012 Traction Wheel Turn, 2'-0" Diameter

|

|

2035.02010 Traction Wheel Turn, 3'-0 Diameter

|

The 2035.02011 Traction Wheel is made from a solid plate wheel,

attached to a section of half track forming the inside track lip. This

wheel rotates around a graph alloy hub and shaft. The non-

rotating half track is formed to match the standard track profile.

The assembly is mounted to a rigid frame for easy installation. The Traction Wheel is finished with powder coating. |

|

The 2035.02010 Traction Wheel is made from a solid plate wheel,

attached to a section of half track forming the inside track lip.

The wheel rotates around a graph alloy hub and shaft. The non-

rotating half track is formed to match the standard track profile.

The assembly is mounted to a rigid frame for easy installation.

The Traction Wheel is finished with powder coating. |

|

|

|

|

|

|

|

|

|

|

|

Click the button of the item you wish to purchase. Contact us for special lengths

|

|

PRICING FOR HORIZONTAL TRACTION WHEEL TURNS

|

| Model No. |

Description |

Weight/lbs. (ea.) |

Price |

| 2035.02012 |

Traction Wheel Turn 24" Dia. X 180° |

100 |

$4,486.65

|

| 2035.02011 |

Traction Wheel Turn 30" Dia. X 180° |

130 |

$4,627.35

|

| 2035.02010 |

Traction Wheel Turn 36" Dia. X 180° |

160 |

$5,813.85

|

|

|

|

|

|

|

|

|

PRICING FOR DRIVE ADDITIONS

|

|

|

|

2035.01371

|

2035.01372

|

|

|

Explosion Proof Motor |

Add |

$3,748.50

|

$3,748.50

|

|

|

Motor Brake |

Add |

$4,249.35

|

$4,249.35

|

|

|

Clutch Brake |

Add |

$7,248.15

|

$7,248.15

|

|

|

Conveyor, Enclosed Track Conveyors, Overhead Conveyors, Overhead Power Chain Conveyor, Safe-Rail, Conveyors, and Zig-Zag

rom your source for material handling equipment.

|

|